Transitioning to a digital factory is no longer a “nice to have” for manufacturers — it’s a make-or-break decision. From disrupted supply chains to huge fluctuations in demand and inflation, the need for agility and adaptability is now more important than ever for survival.

Of course, a shiny, new digital factory can’t appear overnight. There’s still an investment required to undergo a proper digital transformation. However, the benefits far outweigh the risks of remaining stagnant — or worse, getting left behind by competitors already making the transition. Thankfully, integrated product development solutions, like Fusion 360 paired with manufacturing execution systems (MES) make connecting data across entire operations — from design to manufacturing to shipping — as seamless as possible.

But what are the true end results of a digital factory? What can you expect to see after you make the big switch? How easy is it to switch? How can Cadspec help? Here are 5 benefits of a digital factory that lead to better outcomes, profitability, and a stronger competitive edge.

1. Enjoy a quicker time to market

Since the beginning of the Industrial Revolution, it’s safe to say there’s been one core mantra: faster, faster, faster. Automation and finding innovative ways to get products out the door is a cornerstone of the manufacturing industry.

One of the main objectives of digitisation is optimising the manufacturing environment to maximise productivity. Automation, collaboration, and a connected, cloud-based system help information flow faster so products can be produced more quickly. Using Autodesk Fusion 360 and Autodesk Prodsmart enables an organised workflow from the top floor to the shop floor that leads to faster design and production times and cost savings.

2. Unlock greater agility with flexible manufacturing

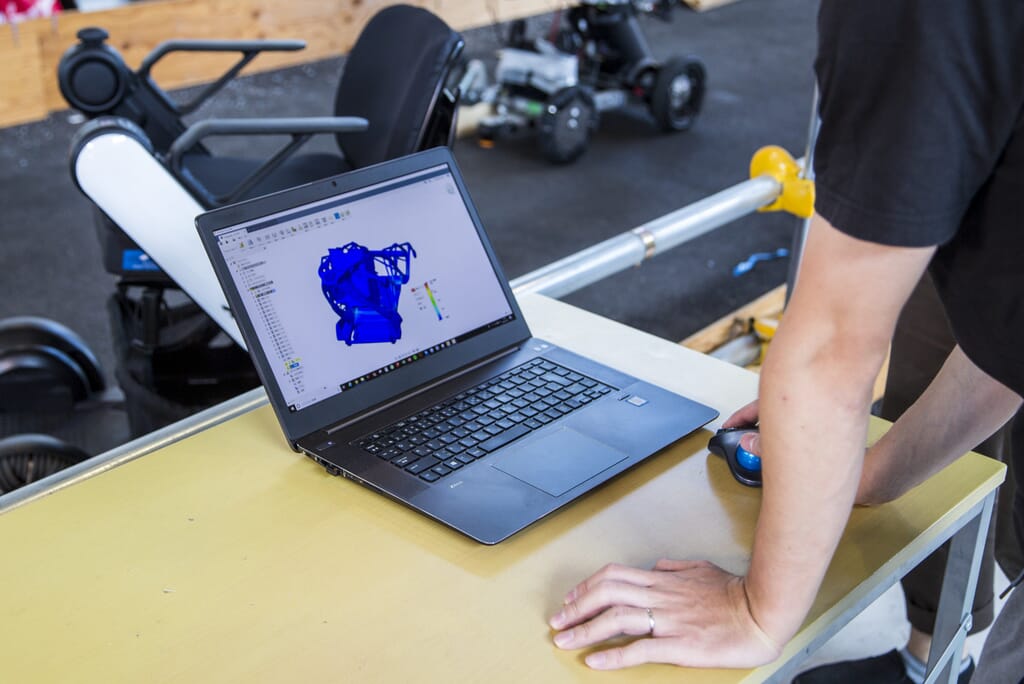

If we’re being honest – flexible isn’t the first term that comes to mind when you think of a factory. Flexible manufacturing refers to becoming more resourceful to quickly change course, find alternative solutions, or make modifications. What’s the easiest way to unlock this ability? Start with software. You’d be surprised by how much digital tools integrated like CAD/CAM/CAE/PCB software and MES can affect your team’s agility. Cadspec have worked with many factory floors up and down the UK enabling these solutions and watching the businesses thrive. From automation to real-time data insights, it’s worth exploring the added flexibility that comes with implementing a digital factory.

3. Meet changing demands with customisation

Whether it’s personalised trainers for a person or diverse batches of products, customers simply don’t want the same thing anymore. It’s not just mass production anymore—it’s all about mass customisation. In todays world, people love individuality and standing out from the crowd.

This may mean small batch runs or new features to an existing product. One customer might order 1,000 standard phone chargers, while another might want 100 phone chargers with a durable cord cable. A third customer might want 10 blue phone chargers with a yellow lead. A manufacturers headache!

Accommodating these customer needs is a huge competitive advantage. Features in Fusion 360 like parametric design tools enable teams to easily create custom products without needing to start from scratch every time.

4. Experience an operational efficiency boost

Manufacturing execution systems (MES) like Prodsmart help manufacturers and fabricators— regardless of their size — automate production management, go paperless, and minimise waste. A real-time system of record for data collection, management, and analysis gives production managers insights to boost operational efficiency from orders all the way through to shipping.

5. Achieve sustainability and your business goals

Many companies are committing to sustainability not only because it’s the right thing to do but their customers are also demanding it. Whether it’s shifting to sustainable materials or reaching a net-zero goal by a certain year, only a digital factory can help achieve a combination of sustainability and business goals.

Using generative design in Fusion 360 at the beginning of the design process is one-way teams are making this shift. Generative design reveals design options that use fewer materials and enables decision-makers to look at all their options to make the best possible decision given their constraints. Whether your goal is light weighting a product, reducing material, or speeding up the manufacturing process, generative design is an easy way to start heading in that direction.

Additionally, using an MES enables teams to better plan ahead for fabrication. Teams can now prevent the over-purchasing of materials, track employee schedules and keep up with sales orders all in one platform.

Ready to start turning your company into a connected, digital factory? Talk to Cadspec, who will be happy to do a factory floor audit and help you get started.

Related Courses