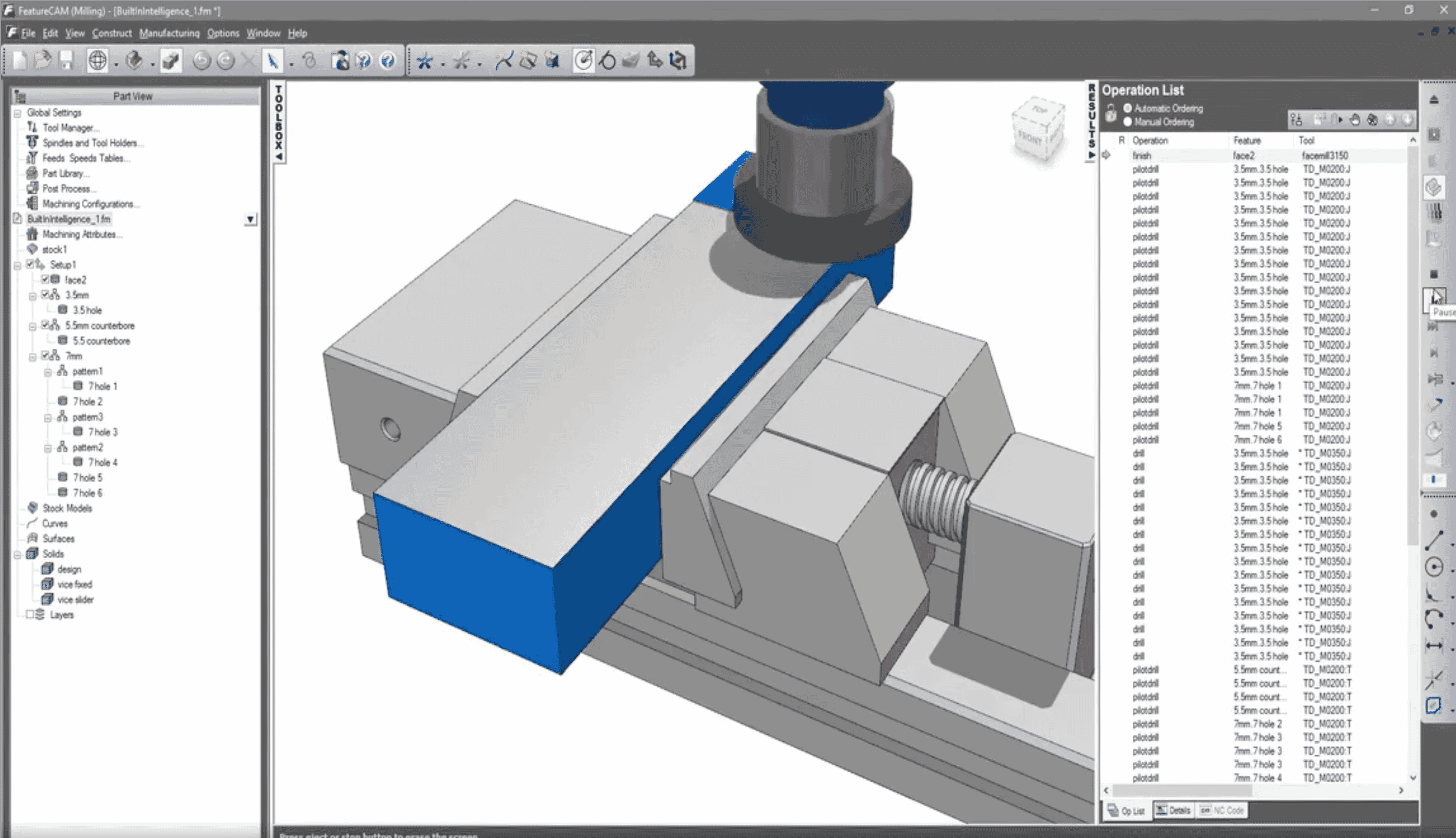

Autodesk FeatureCAM software automates your workflow from design to NC code. It allows you to reduce your programming time and produce consistent, high quality results for CNC milling, turning, multi-tasking and wire applications.

Creating features and operations with automation removes repetitive tasks, eliminating the scope for human error. This increases programming consistency and enables a level of predictability to produce reliable NC code for maintaining part quality.

Comprehensive machine support

FeatureCAM supports a comprehensive range of CNC applications including milling, turning and wire applications. The software caters to the programming needs of 3-5-axis mills, multi-tasking turning centers, Swiss-type lathes, wire EDMs and more.

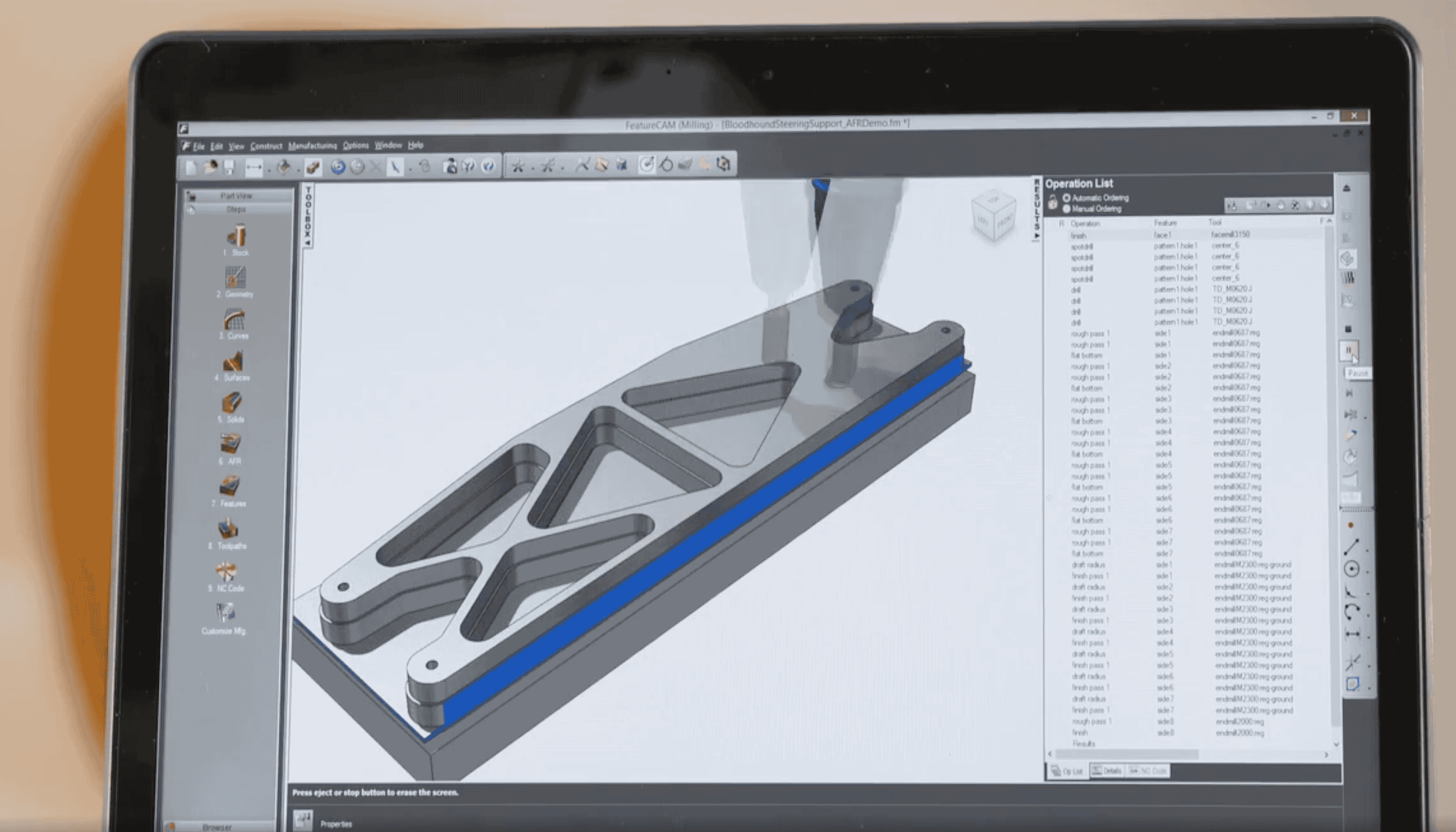

Standardise practices and promote repeatability

FeatureCam takes the manufacturing knowledge of the programmer to intelligently make decisions and produce results. This encourages manufacturers to standardise their best practices, from existing quality standards and promote repeatability between all employees using the same set-up.

Simulation and safety

Use FeatureCAM collision avoidance tools to create safe, collision-free toolpaths. Visualise your programming with machine tool simulation to validate your work prior to machining. Check for collisions that could results in additional cost or machine downtime.