Fusion with PowerInspect

PowerInspect makes inspecting large, complex & layered parts simpler.

Autodesk Fusion with PowerInspect is 3D measurement software for offline programming of inspection routines that monitor and control manufacturing processes.

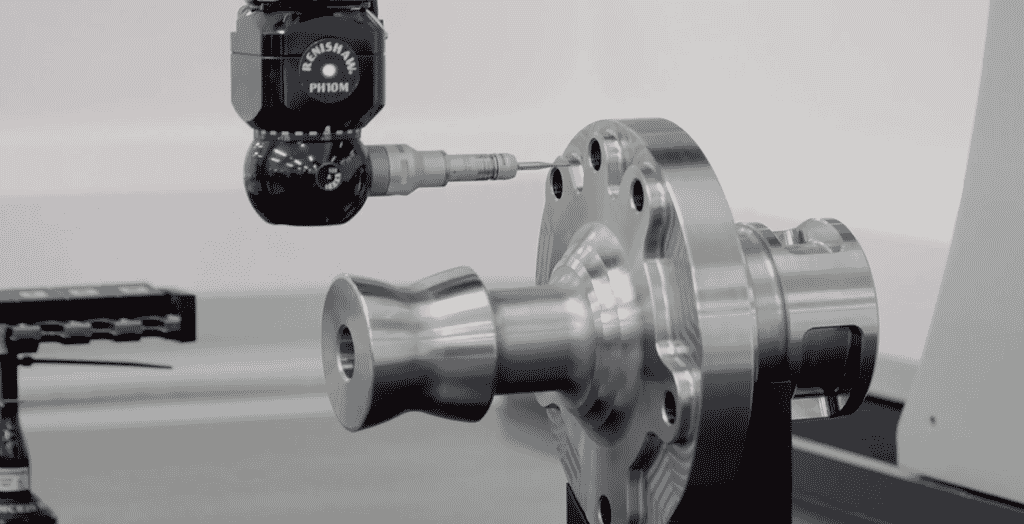

Measure complex 3D shapes with greater quality control. Fusion with PowerInspect supports CNC coordinate measuring machines (CMMs), portable inspection devices, and other inspection hardware.

-

Why PowerInspect? Overview

Autodesk PowerInspect (formally known as Delcam) is the worlds leading 3D measurement software that offers a powerful way to inspect, validate, and manage quality control for all measurement equipment.

PowerInspect Ultimate allows you to thoroughly inspect your complex free-form shapes. Fusion 360’s tools provide strong CAD support, from flaw monitoring to providing quality reports for final project approval. This will help you enhance quality control before, during, and after production.

Meet Production Goals

PowerInspect software allows you to not only meet your production goals but to avoid expensive rework in the process. Save costs by identifying inconsistencies early on in the manufacturing process and reduce the number of human errors with better real-time monitoring.

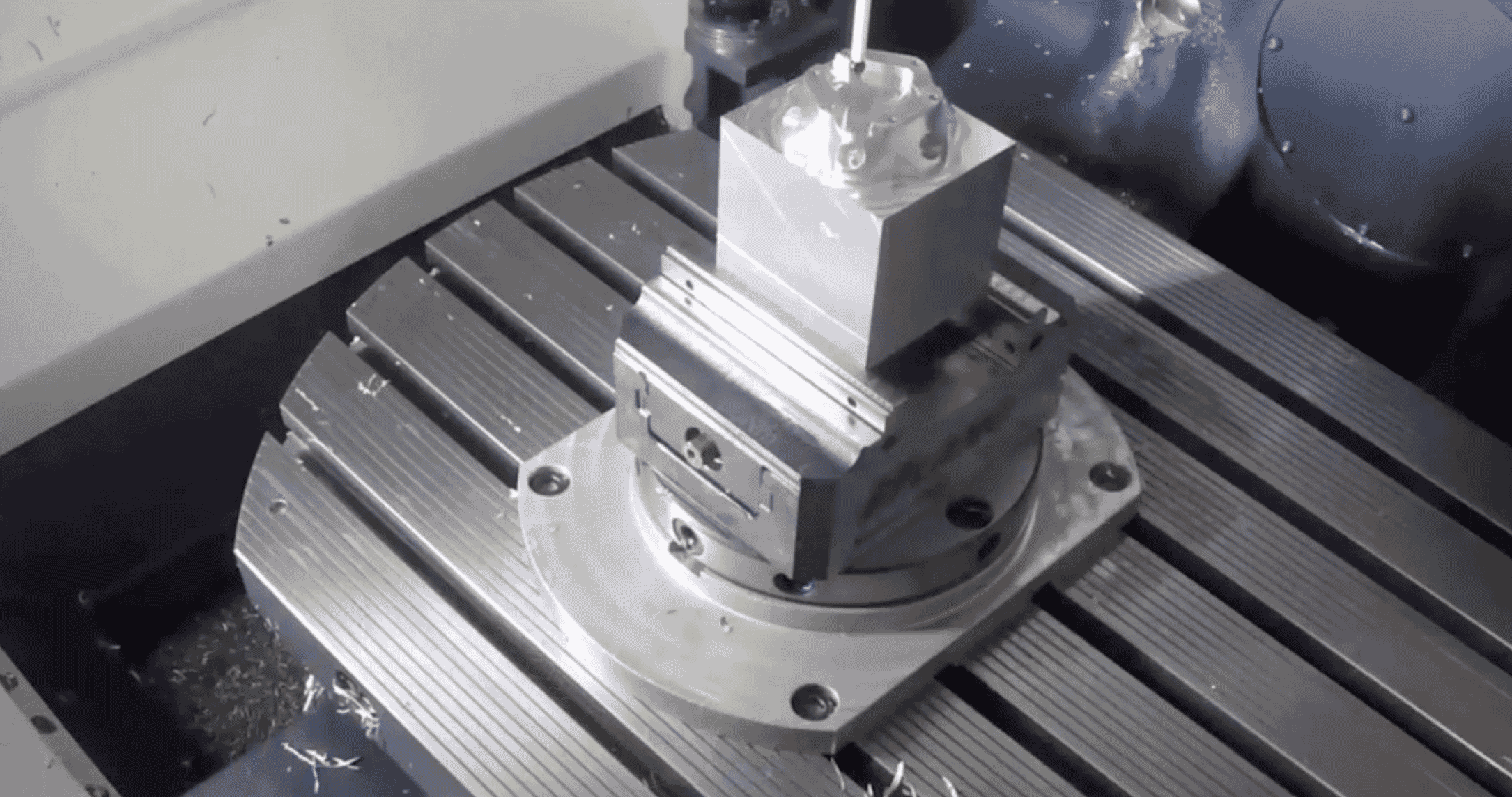

Perfect Partner for PowerMill

Combining PowerInspect with PowerMill CAM software will ensure the quality and accuracy of your machined parts maintained throughout the manufacturing process.

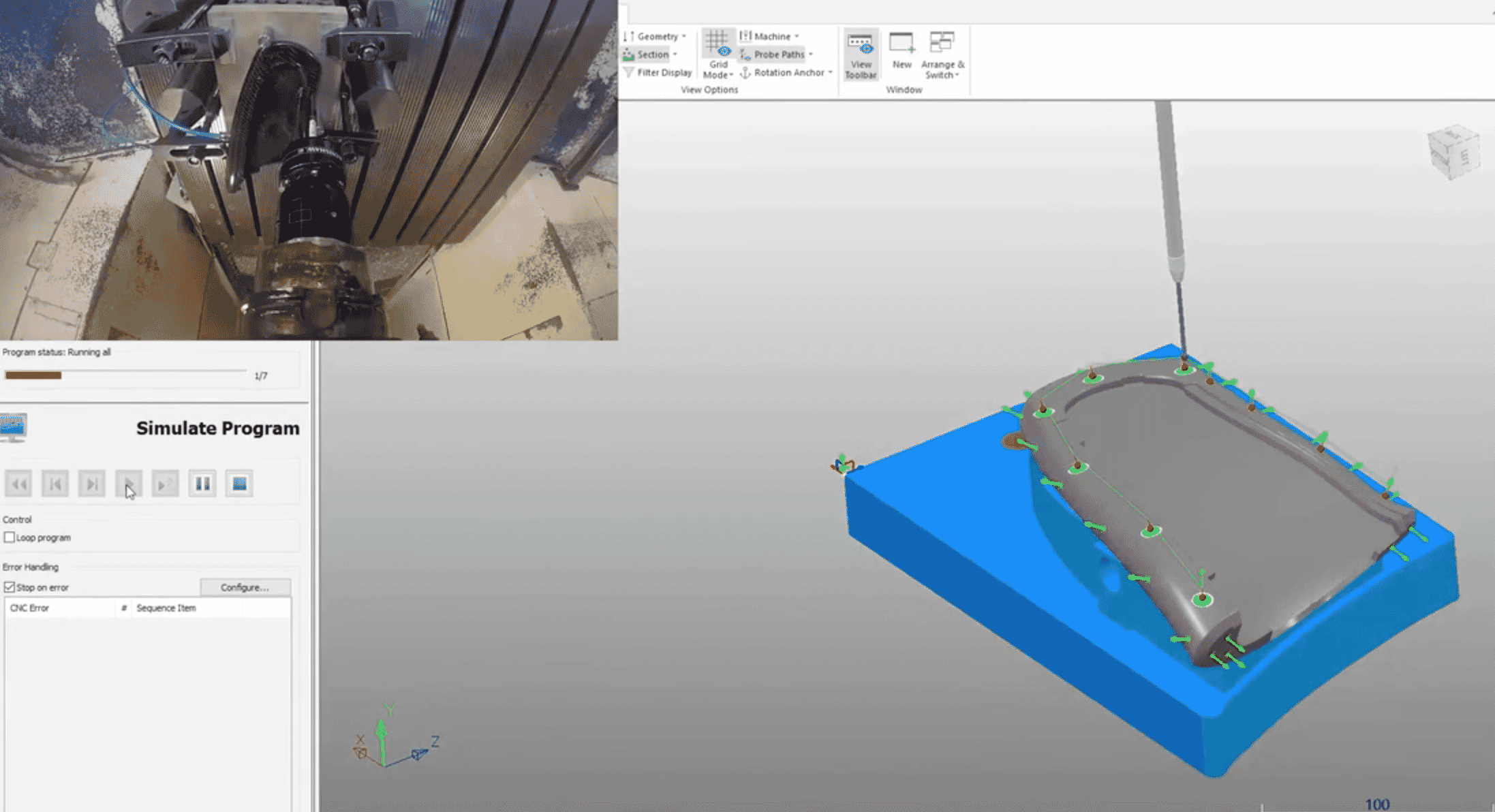

Read MoreOn-Machine Verification

Whilst still in On Machine Verification (OMV), PowerInspect will measure components and acquire a complete inspection solution. This machine tool probing assists with making informed decisions with regards to scrap or rework of the component.

-

Fusion with PowerInspect pricing

Product Cost Fusion with PowerInspect CLOUD - New Single-user Annual Subscription £ (inc. VAT) Fusion with PowerInspect CLOUD - New Single-user 3 Year Subscription £ (inc. VAT) -

Frequently Asked Questions

-

Does PowerInspect provide me with a comprehensive report at the end?

Yes! It helps you create attractive reports that are easy to understand. Graphical labels and dimensions simplify visualization and the CAD View report feature allows you to place images from the CAD view anywhere in the report.

-

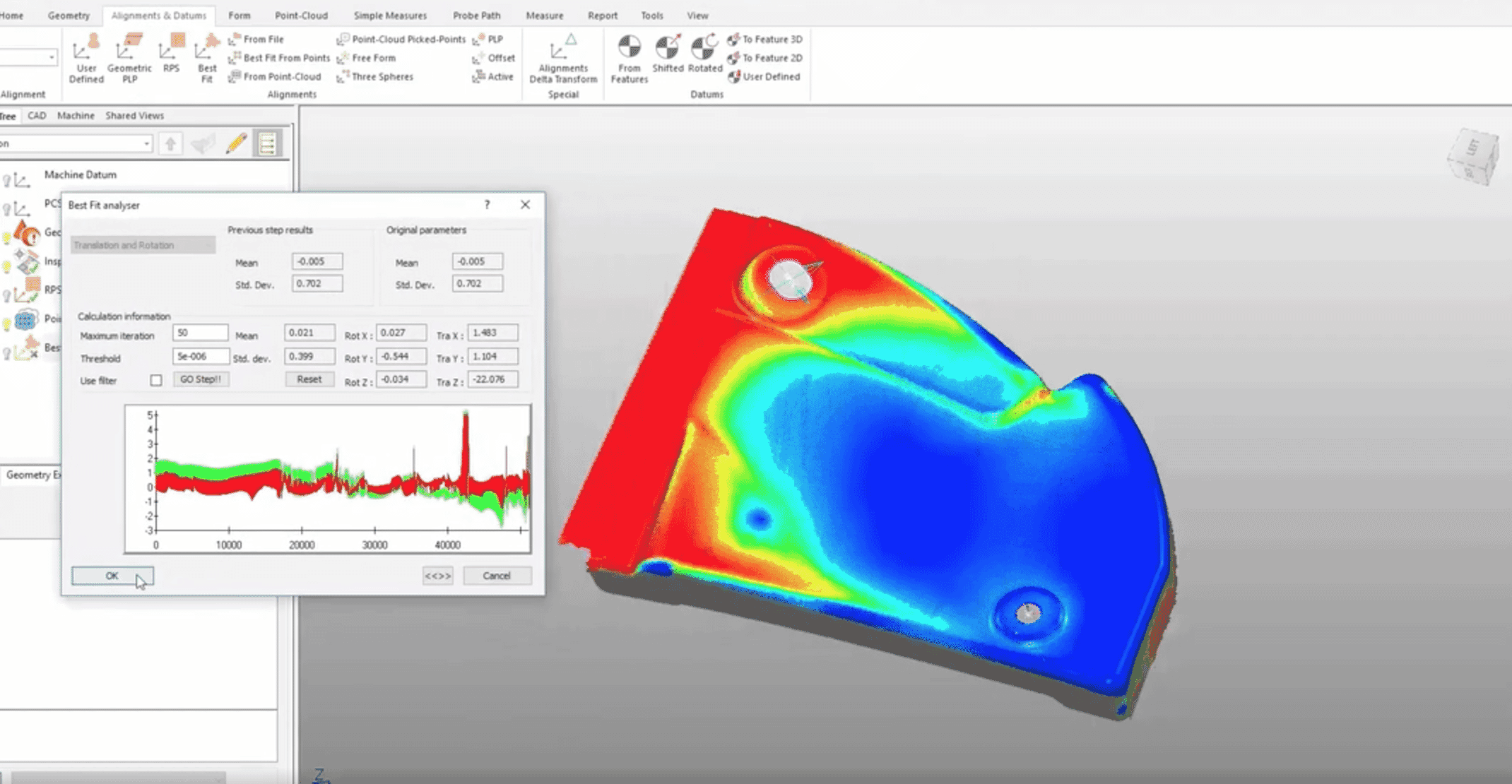

Can PowerInspect automatically realign geometry to suit original CAD model?

Yes, PowerInspect can automatically realign geometry to match the original CAD model. The software also considers stresses and strains on the part, ensuring accurate alignment and measurement.

-

What CAD formats will PowerInspect work with?

PowerInspect works with all mainstream CAD formats, offering maximum flexibility to handle data from customers or suppliers. This ensures compatibility and ease of use across various design files.

-

Is the software easy to pick up? If not – what training would you recommend for a first time user of Autodesk PowerInspect?

If users have been using previous inspection software then minimal training will be required. Some form of formal training is recommended to ensure best practice. For further information on PowerInspect training, head over to our training calendar.

-

What metrology devices can PowerInspect work with, CMM/White Light/Blue Light?

PowerInspect is compatible with a variety of metrology devices, including:

- CMM: Works with either native protocols if supported or via I++ standards.

- Articulated Arms: Compatible with arms that have scanners attached.

- Blue Light Scanners: Supports blue light scanning technology.

- On-Machine Probing: Works with post-processors to support most major control types.

- This versatility allows PowerInspect to integrate smoothly into various inspection workflows.

-

What is PowerInspect?

PowerInspect is a 3D measurement software that provides a comprehensive solution for inspecting, validating, and managing quality control across various measurement equipment. It offers powerful metrology tools designed for manufacturing, enabling users to ensure precision and maintain high standards of quality in their processes. PowerInspect supports a wide range of devices, making it a versatile tool for various inspection and measurement needs.

-

Does PowerInspect provide me with a comprehensive report at the end?

-

PowerInspect Software Reviews

"PowerInspect & Autodesk are just part of our racing team now"To get the top performance we want, we have to use this software to get us there. We use Romer Arms and PowerInspect to locate the body panels for the cars and exploit the tolerances. We couldn't see the team without it!Engineering Manager | Stewart-Haas Racing"Manufacturing & Inspection working together"Integration between manufacturing and inspection allows us to serve important industries for quality assurance.Proprietor of Business | ITM Industrial Task Management