Autodesk Inventor

Autodesk Inventor software is professional-grade 3D CAD software for product design and engineering.

Work efficiently with a powerful blend of parametric, direct, freeform and rules-based design abilities.

-

Autodesk Inventor Software Overview

Autodesk Inventor provides 3D mechanical design, simulation, tooling creation, and design communication that help you cost-effectively take advantage of a Digital Prototyping workflow to design and build better products in less time.

Top Inventor features include:

- Shape Generator

- Parametric Modelling

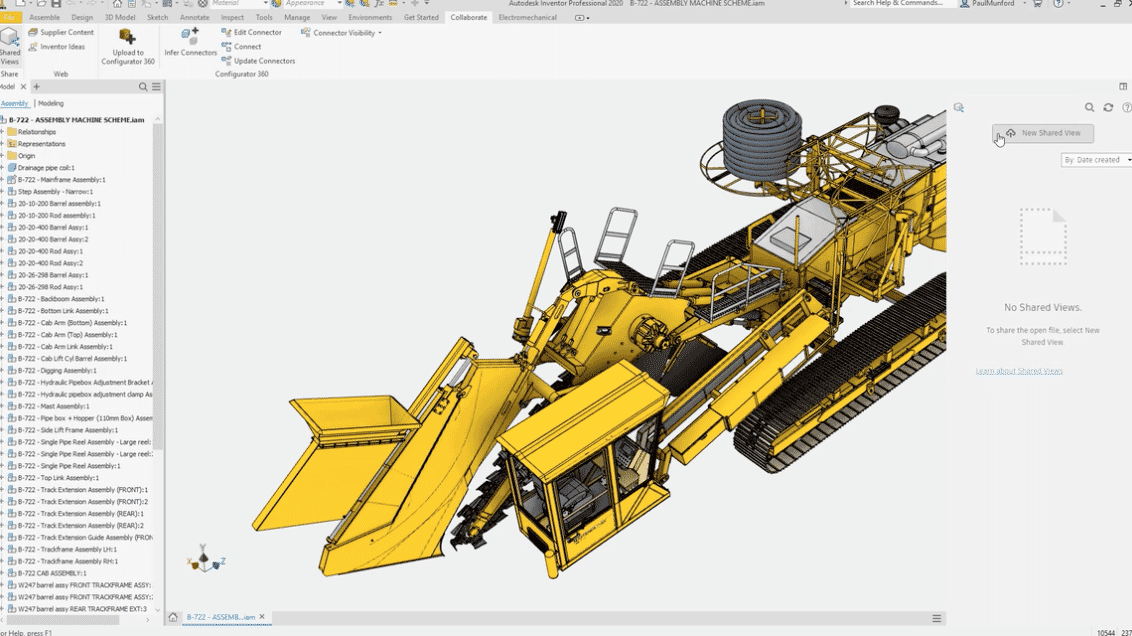

- Assembly Modelling

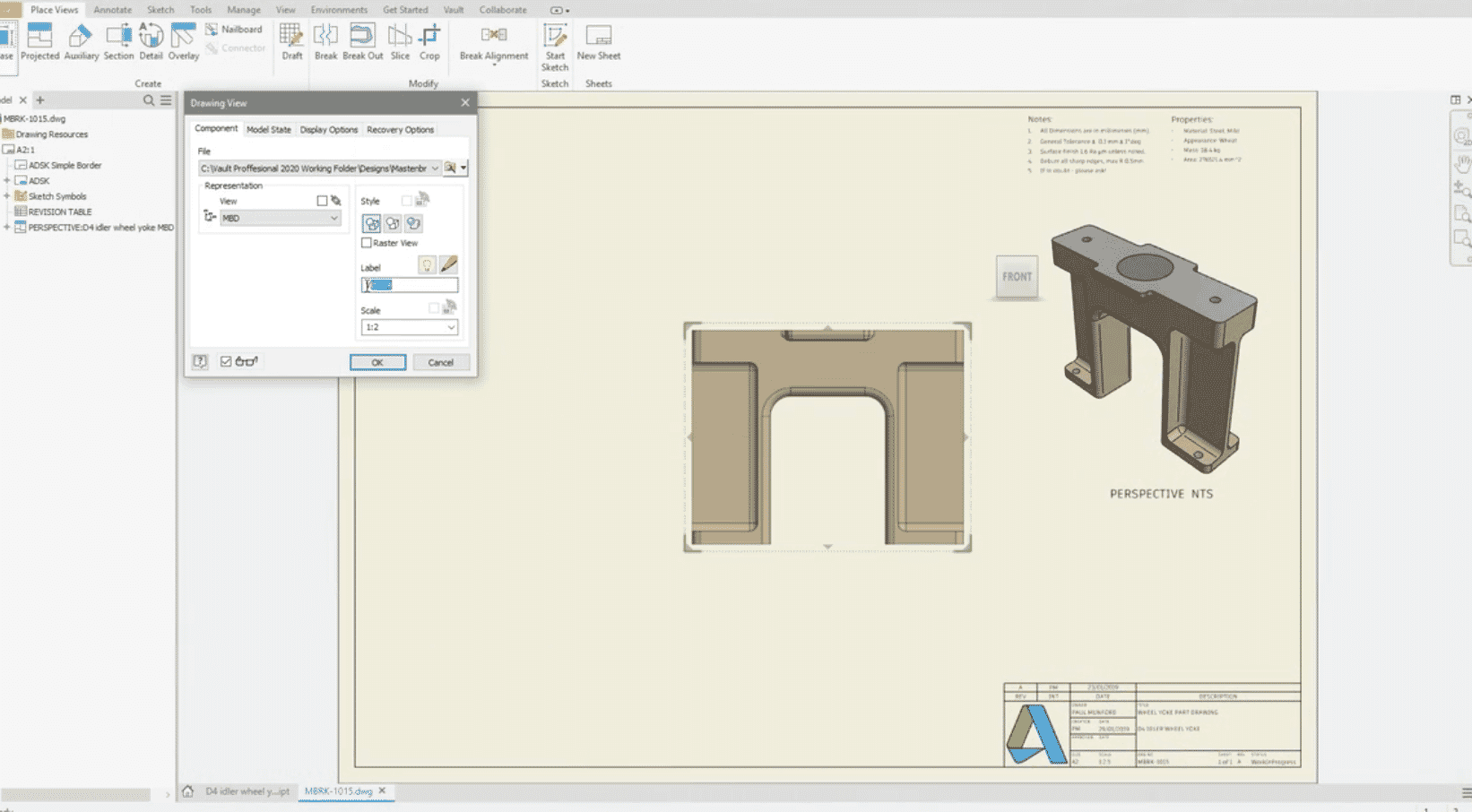

- Drawing Creation

- Work with non-native data

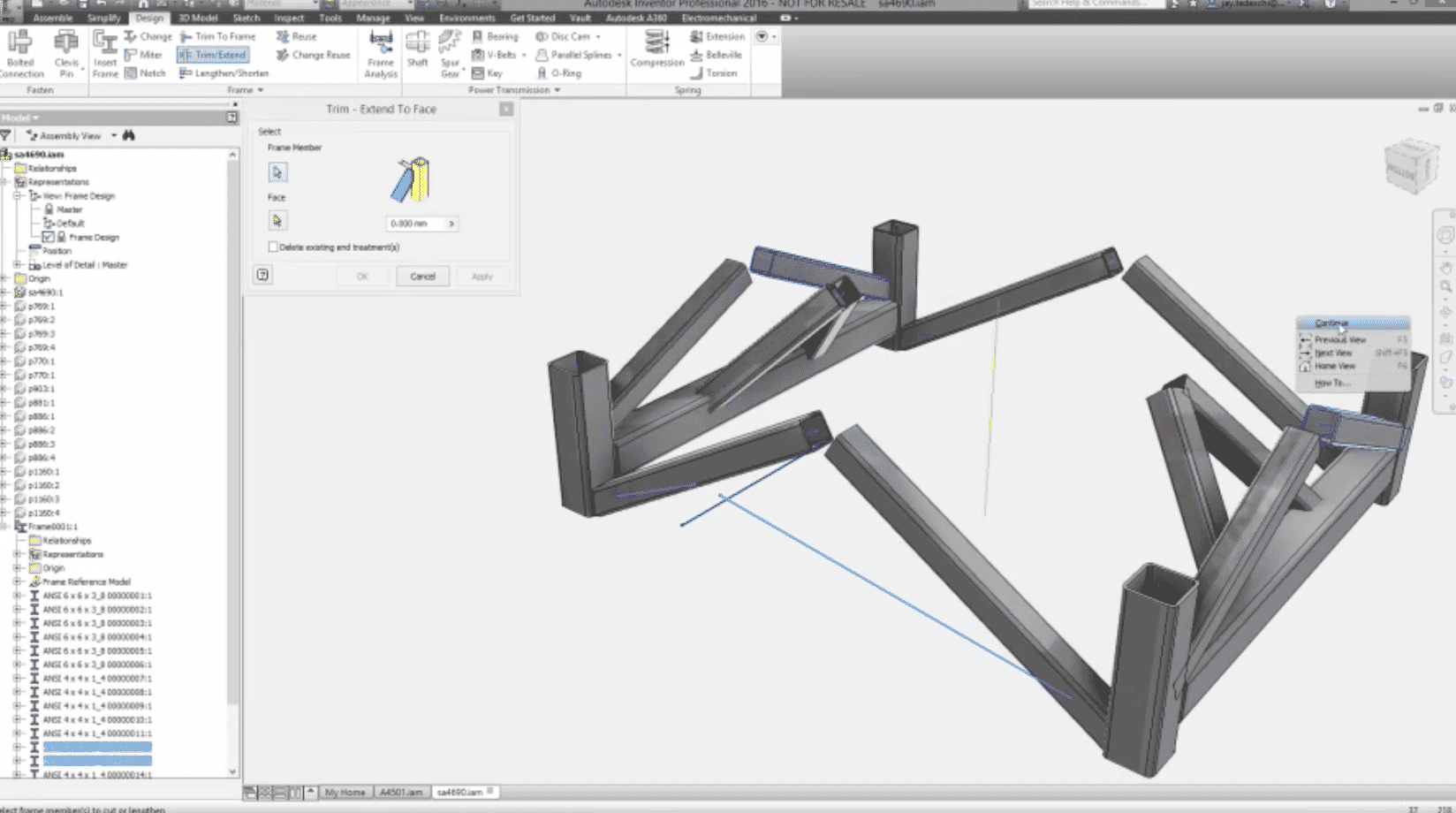

- Automated frame design

- Design Automation

- Shared view collaboration

- BIM Interoperability

- + more.

-

Frequently Asked Questions

-

Can Inventor complete FEA simulation?

Yes, Autodesk Inventor can perform FEA (Finite Element Analysis) simulations to analyze stress, strain, and other physical behaviors of designs.

-

Can Inventor export a Bill of Materials? (BOM)

Yes, Autodesk Inventor can export a detailed Bill of Materials (BOM) directly from the design or assembly. It includes part numbers, quantities, and descriptions, and can be exported in formats like Excel, CSV, or XML. This makes it easy to share with manufacturers and manage production planning efficiently.

-

Can Inventor output an STL file?

Yes, Autodesk Inventor can export STL files, and it can also export STEP and IGES files for compatibility with other software and manufacturing processes.

-

Does Inventor have nesting facilities?

Yes, Autodesk Inventor has nesting capabilities. You can learn more about this feature in the training courses we offer.

-

Does inventor have any CAM facilities?

Yes, Inventor offers CAM capabilities through Inventor HSM. For more details on how it can enhance your manufacturing process, contact our team.

-

Is Inventor part of the Autodesk PDM collection?

Yes, Autodesk Inventor is included in the Autodesk Product Design & Manufacturing (PD&M) collection. This suite provides a comprehensive set of tools for product design and manufacturing, integrating Inventor with other key Autodesk applications.

-

I’m a previous Solidworks user, would I need training on Inventor?

Yes, we recommend full training. While many concepts will be familiar, Autodesk Inventor has its own unique interface and features that differ from SolidWorks. Training will help you transition smoothly and make the most of Inventor’s capabilities.

-

Whats the difference between Inventor and Inventor LT ?

Autodesk Inventor offers a comprehensive suite of tools for creating both parts and assemblies, as well as advanced features for simulation and documentation. In contrast, Inventor LT is a more streamlined version that focuses solely on single-part design, lacking assembly creation and some advanced functionalities.

-

Can Inventor complete FEA simulation?

-

Reviews

"Inventor drives efficiency and leads"Without Autodesk Inventor, we wouldn’t be able to translate the customer’s desires into a workable design as easily. Now our quotes and drawings are much more accurate.Head of Technology & Purchasing | Vent-A-Hood"Avionics enclosure design"Autodesk Inventor and CFD in particular allows multiple iterations and optimisations of each design. This means we can very quickly optimize any part of the designCarlo van Schalkwyk, Senior Systems Engineer, S-PLANE Automation (Pty) Ltd

There are a range of options available – for a bespoke quote, please get in touch