Discover how Cadspec’s experts provided the Autodesk software and CAM training to help a sector-leading prosthetics expert improve its service and innovation

A prosthetics innovator setting the pace

Founded in 1890 and employing 900 staff, Blatchford is one of the world’s most respected innovators in the field of prosthetic technology, bespoke seating solutions and orthotic devices. Driven by a passion for redefining and forging the future of mobility, Blatchford works closely with patients, professionals, clinics and caregivers, providing state-of-the-art products that span from revolutionary units for knees and ankles to complete limb systems.

![]()

With Blatchford citing one of its mission statements as “defining possible by testing the impossible”, it’s no surprise that this visionary firm is committed to using the most powerful and flexible software. And when Blatchford’s award-winning team became frustrated by their current post-processor – telling Cadspec that “we had multiple issues that were costing us time and making programming awkward” – we were pleased to advise them on solutions.

Suggesting the optimal software and CAM training

Regardless of our experience in a given sector, the Cadspec team’s first move is always to hold an in-depth conversation with our new client and find out more about their intended application. Given that Blatchford’s work spans from to creating microprocessor-controlled hydraulic limb units to designing the revolutionary Performance-Response Technology ® that mimics the natural movement of lower limbs, we knew the team would require advanced Autodesk software and the knowledge to unlock its full potential.

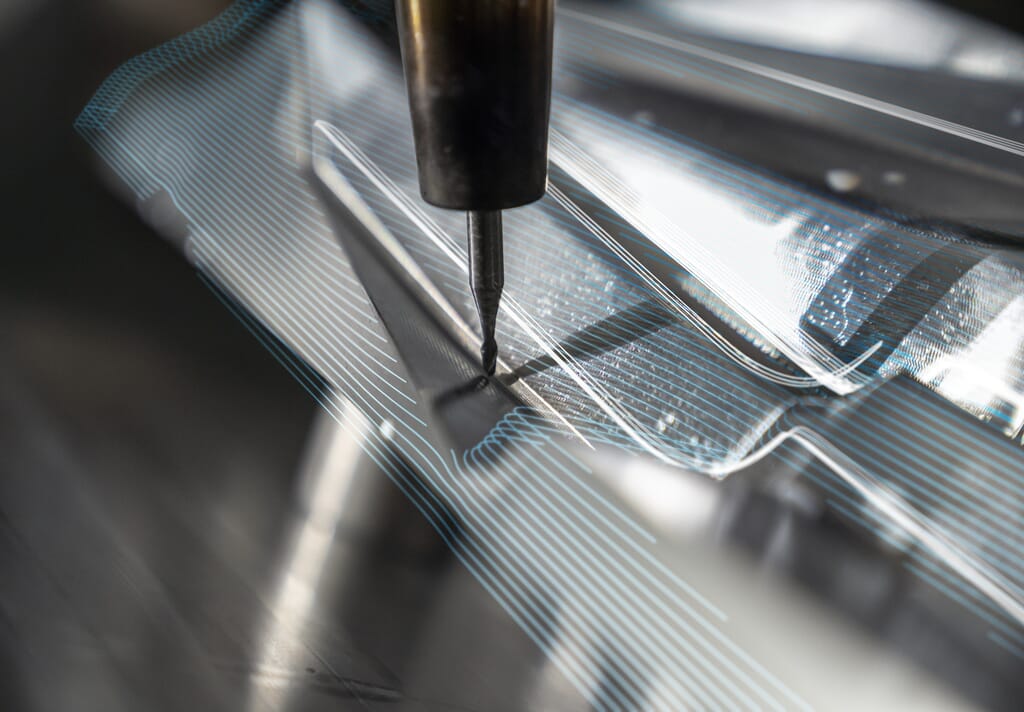

After Blatchford shared the specifics of what they hoped to achieve, it was agreed that we would provide Fusion 360 with PowerMill (renowned as expert high-speed and five-axis machining software for manufacturing), alongside Fusion 360 with FeatureCAM (advanced CNC programming software, with feature recognition to automatically identify and create features). As Blatchford’s Manufacturing Engineer Justin Badenhorst explains:

We use PowerMill for its flexibility in editing toolpaths and machining complex parts.

The optimal software is an important first step, but a vital strand of Cadspec’s offering is giving our clients the skills to harness its capabilities. In Blatchford’s case, we helped the team build on their already stellar knowledge with our PowerMill Advanced Training, covering topics from 3 axis machining and drilling to five axis swarf machining. Finally, for complete peace of mind moving forward, we offered Blatchford our Advanced Technical Support.

A very satisfied customer

It was a pleasure to advise Blatchford on solutions to facilitate their important work, and Cadspec was delighted to hear the feedback.

Justin Badenhorst commented:

Together with Cadspec, we updated our post processor which resulted in faster cycle times and more reliable and customisable code to suit our machine tools. The results and benefits are more stable processes and reliable code. Also, a better understanding of PowerMill with some additional advanced training for more complex five axis tool-paths. Would we do business with Cadspec again? Absolutely. Working with Joe Sklenar has been great, his in-depth knowledge of PowerMill and post writing is fantastic. We are saving 3-5% on average on cycle times with our updated post processor now.

Joe Sklenar, CAM specialist at Cadspec commented:

It has been a joy to work alongside Blatchford’s in helping them achieve their goals, great people! I consider them both friends and customers. True professionals, highly skilled, and interesting line of work, not to mention ingenious setups and workflow practices. The complexity of their work has also been educational for us expanding our ability to provide not only customised CAM training but unique Post-processor solutions.

To discover how Cadspec can help with your project, get in touch with the team today.

Related Software