With a rich legacy spanning over six decades, Lesk Engineers stands as a venerable sub-contract machining company. Throughout its extensive history, Lesk Engineers has been a reliable provider of turning, milling, and grinding services to a diverse yet discerning customer base. This clientele spans across multiple industries, with a notable presence in the military, aerospace, and automotive sectors, among others.

Lesk Engineers has established itself as a go-to solution for precision machining, catering to the unique and stringent requirements of its customers. The company’s commitment to delivering high-quality services is evident in its ability to navigate the complex and exacting standards of the military, aerospace, and automotive sectors, reflecting a dedication to precision and excellence.

The Challenge

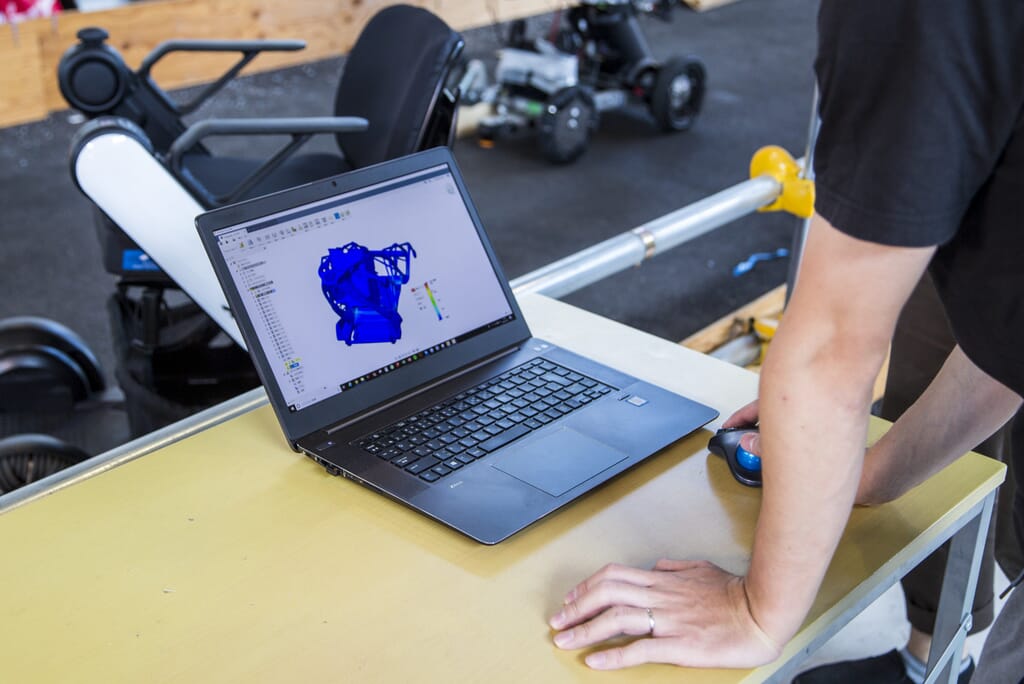

The primary reason behind the adoption of new Autodesk software stemmed from the imperative to transition a new set of personnel swiftly and efficiently to offline programming.

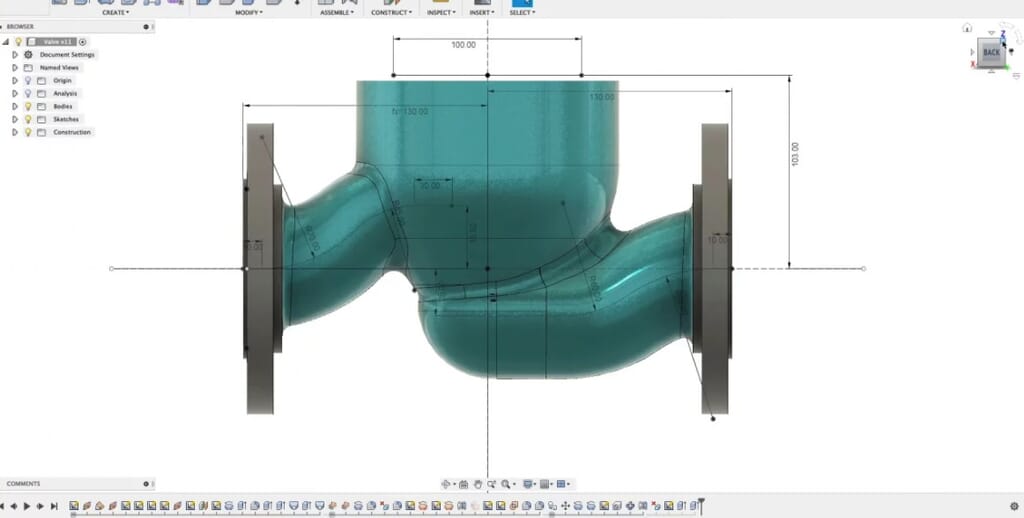

Recognising the need for a seamless onboarding process, the decision was made to leverage cutting-edge technical software from Autodesk (Fusion 360), coupled with the assurance of reliable long-term support from a trusted supplier Cadspec. This strategic move was driven by the goal of not only meeting immediate requirements but also establishing a sustainable and robust framework for offline programming that aligns with the latest technological advancements.

Why Cadspec?

The primary factor influencing the decision to engage Cadspec for support in this venture was not only the existing long-term relationship with the sales representative but also the reputation of Autodesk manufacturing partner Cadspec.

Gary Ketteringham, Managing Director, Lesk Engineers:

At Lesk Engineers we’ve known Louise for a while, so taking her expert technical advice on board and being backed up by a professional team at Cadspec – the transition over to Fusion 360 was easy.

The Future

The purchase of Fusion 360 with the Machining Extension, facilitated by Cadspec, has proven to be an ongoing success for the organisation. The outcome thus far has been highly favourable, with the machinists benefiting from excellent training, resulting in the successful machining and delivery of numerous new parts through the offline process.

Gary further commented:

The extensive support from the technical team at Cadspec has been nothing short of exemplary. Their commitment to assisting with complex problems, going above and beyond, has been instrumental in overcoming potential roadblocks and ensuring a smooth operational flow.

Related Software

Related Courses