Who are Pro Handling Solutions?

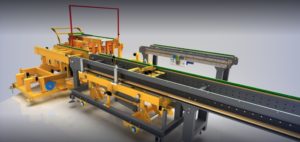

Pro Handling Solutions (PHS) are a Material Handling & Automation Device Manufacturer. They produce automation equipment for the Warehousing, Automotive, Food & Beverage, Medical, Aerospace & Energy Production Industries.

Their manufacturing method is a mix of bespoke design with standard products, giving the integrator the flexibility to provide the end-user with their exact requirement, at the same time keeping design and manufacturing costs to a minimum. PHS’s wide range of Conveyor Equipment and Materials Handling Products allows the integrator to provide a complete system, with all the functionality the end-user desires.

The Challenge

PHS wanted to make significant gains across multiple factors that they saw as benefits for the growth & sustainability of their business. Using 6 Sigma, the PHS team identified each core factor, used the Autodesk Product Design & Manufacturing Collection and then they implemented a change of process control to ensure success:

1.Research and Development

Parametric Design: They created products using Autodesk iLogic. Using a form to generate 3D Models & 2D Manufacturing Drawings. This allows an operator to configure designs at greater speed and significantly lower cost.

3D Modelling: Allowing their customers to see their devices fully developed at the time of quotation and offering greater confidence in their decision making.

2. Engineering Time (PHS bought their products to market faster)

3. Representative Modelling for each quotation

Implementing the benefits gained from Parametric Design & 3D Modelling, PHS’s quotations are not a visual representation of their proposals, they are manufacturable devices from their library to suit the need of the project.

4. Engineering Simulation & Analysis

When issues occur, PHS is able to simulate the problem with greater detail than ever. Identifying and corroborating calculations to ensure the correct operation of devices.

5. Production Control & issue of drawings for manufacture

Integration of their production control department directly with their production assembly teams by using Inventor and AutoCAD to issue drawings, bill of materials & graphical representations of assembly instructions.

6. Quality

PHS are able to generate & issue tolerance generated drawings at a fast pace. This is so their inspection department can check each part as it arrives & has a clear instruction of what and how a part should be inspected.

Why Autodesk?

PHS engineers have used AutoCAD as a standard for many years and did not want to bring in something new for their teams to learn, as this can be a hindrance to productivity. Instead, their focus was to take what they already know & develop new processes to expand the capabilities for a company-wide benefit & deliver a direct benefit to their customers.

Alex Bordino, Manufacturing Applications Specialist at Cadspec commented:

It’s been great to collaborate with PHS and enhance their design and manufacturing process. By fully utilising the Autodesk PDMC, PHS are able to really differentiate from the competition and do more for their customers. Adopting the PDMC as part of the design workflow has driven the business forward and uncovered new efficiencies that were previously unknown. Cadspec looks forward to supporting the PHS team with the continual evolution of their design process.

Autodesk software and Cadspec together helped PHS implement these benefits. Cadspec sold PHS the Autodesk Product Design and Manufacturing Collection and then carried on to develop a custom training course for PHS that targeted their specific requirements. With this training under their belts, they were able to implement their desired changes into reality within a month!

Lewis Hunt – Business Development Manager at PHS commented:

The results have been outstanding!

Every quotation that Pro Handling Solutions now produce includes full factory design with all their own equipment. They are able to simply change models to develop new products in a fraction of the time and can now generate production drawings at a rapid pace & test modifications prior to procurement. Moreover, with their new representative modelling, it allows their customers to see exactly what their investment will achieve.

Results

Lewis explained to us that investment in their own services has lead to an increase in their success in winning projects & delivering the required results to within project. Showing new customers their historic projects in full 3D Factory Design has meant that new customers are more comfortable with PHS & what they can achieve as a company.

Moreover, PHS has been able to drive down the cost burden of doing business & directly pass the savings back into their product lines and offer more competitive pricing.

Lewis commented:

The Autodesk cloud has allowed me to virtually show my customers my products without giving away my intellectual property. In addition to all of this, the Autodesk Product and Manufacturing collection has so much more to offer that we are slowly integrating into our business as we grow.

Related Software

Related Courses