Fail Quicker with Accelerated Design

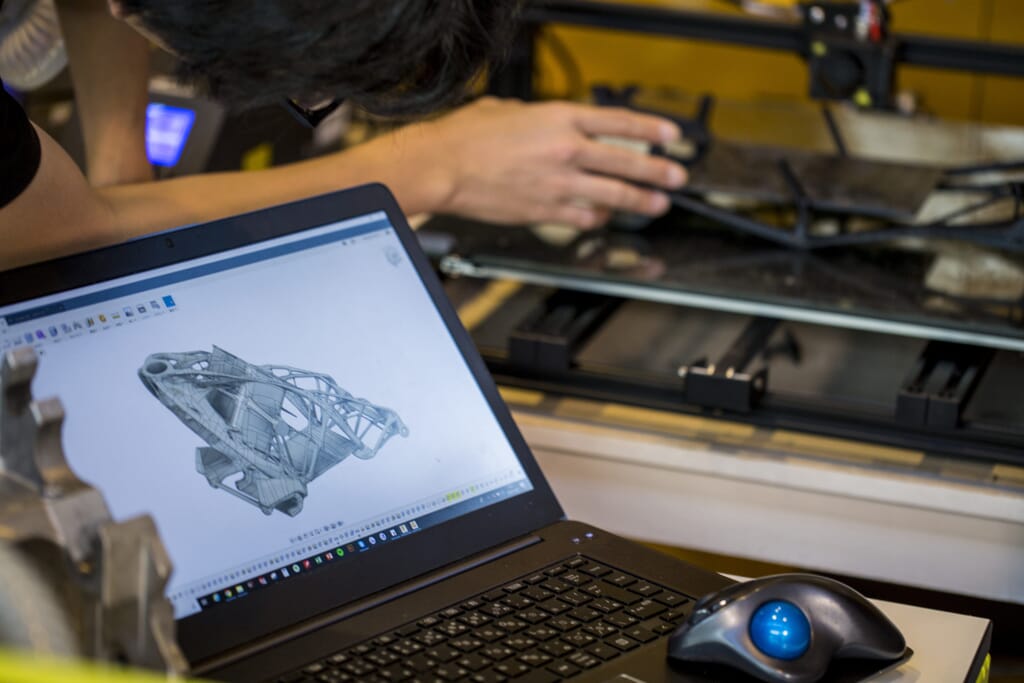

The project design process involves multiple iterations of products, each needing to be validated and improved upon. In proving a design’s function (or lack thereof) in the fastest possible time, project completion will arrive much more swiftly. This is where PDMC and Autodesk’s Vault can help.

PDMC is the abbreviation for Product Design and Manufacturing Collection. As moniker’s go, it’s surprisingly descriptive – but how does it specifically accelerate design processes? We’ve enlisted the help of our Sales Director Richard Parkes, who has all the know-how to walk us through the subject of using PDMC products for accelerated design.

Hi Richard, can you tell us a little bit about yourself and your background?

I’ve been in the engineering industry since leaving university, when I started as a PLC programmer for a chemical plant. Not long after that I transitioned into a sales role and have been working the CAD industry ever since!

Could you give us a brief overview of what PDMC (product design and manufacturing collection) is?

It’s a suite of engineering products developed by Autodesk that enables engineers to design and manufacture products better and faster. Plain and simple, PDMC will enable you to design a great product. This happens through managing the data associated with the project process, and PDMC works in the background to make this management far more effectively. Many people will see this as a bland subject, but business critical information is obviously important. Therefore it’s crucial that the information is handled properly in order to streamline workflows and make them particularly efficient.

Vault is one of the engineering programmes encompassing PDMC, how can it help designers improve their processes?

Vault enables engineering companies to reuse large portions of their CAD data. Traditional manufacturing companies would consistently reinvent the wheel, wasting a lot of time. But reusing the old data helps you to make new variations of older products, helps with revision control, and distributing data to other members of the organisation that need access to it.

How does accelerated design impact projects across their lifespan?

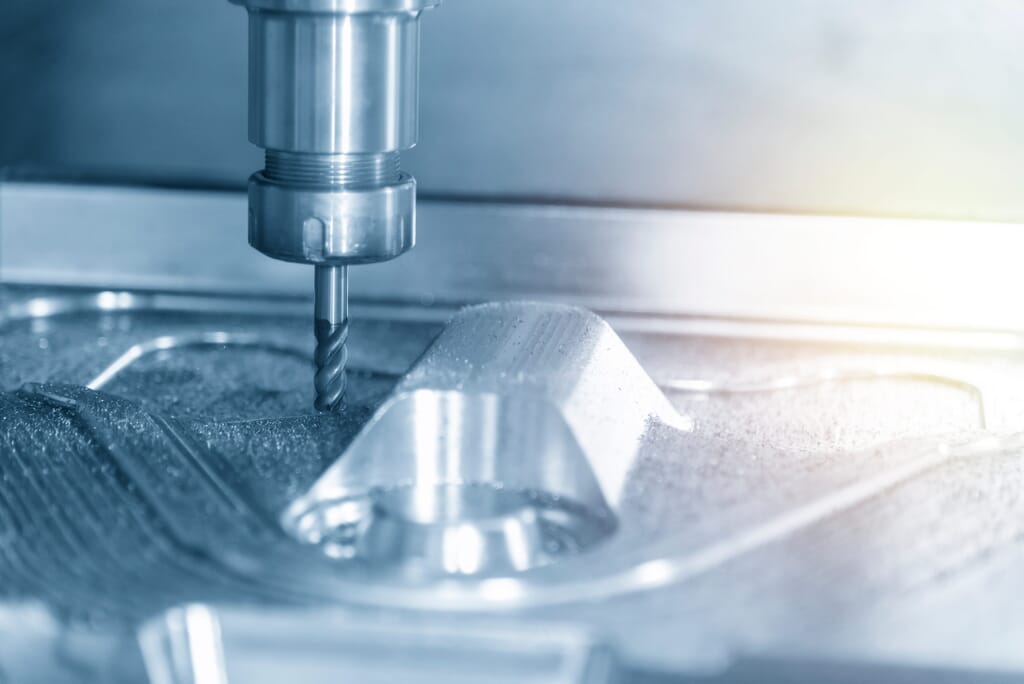

Well you can fail quicker with accelerated design! Going back to traditional design, a lot of the process is restricted in speed through the physical drawing of lines. Using digital methods most products can be out of the door quicker, which satisfies customer needs, improves overheads and makes more money.

Could you tell us more about the knock-on effects of part alterations? (with regard to production assemblies).

Altering any drawing in AutoCAD is a pain in the backside. It’s the bane of every design engineer’s life. What the design collection enables you to do is quickly and easily make the design changes necessary to complete the job.

And how is vault a solution to this problem?

It utilises functions that enable you to copy and reuse data, and allows the finding of that data much faster. Some people spend way too much time endlessly scrolling through drives. All of the metadata associated with the CAD project can be easily searched for. It makes the reuse of data much smoother when you can actually find it easily.

Have you got any examples of customers utilising PDM particularly effectively? (that you can talk about)

The standout examples have all included advantages brought by PDMC to more traditional companies with a 2D drawing mindset. Bringing design improvements to digital prototypes that will ultimately be manufactured is so much less painful when incremental prototyping takes hours instead of weeks in some instances. This is due to the digital model holding much more valuable information on the model and enables businesses to utilise this data much more effectively than just lines, arcs and circles on a page of paper.

If you have any queries about Autodesk Vault or anything else related to this article, contact us today.

Related Courses