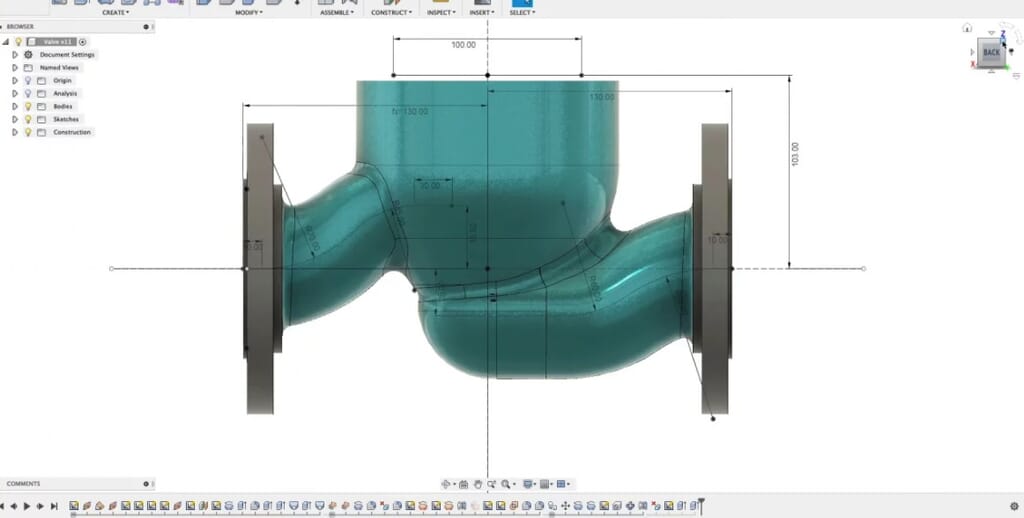

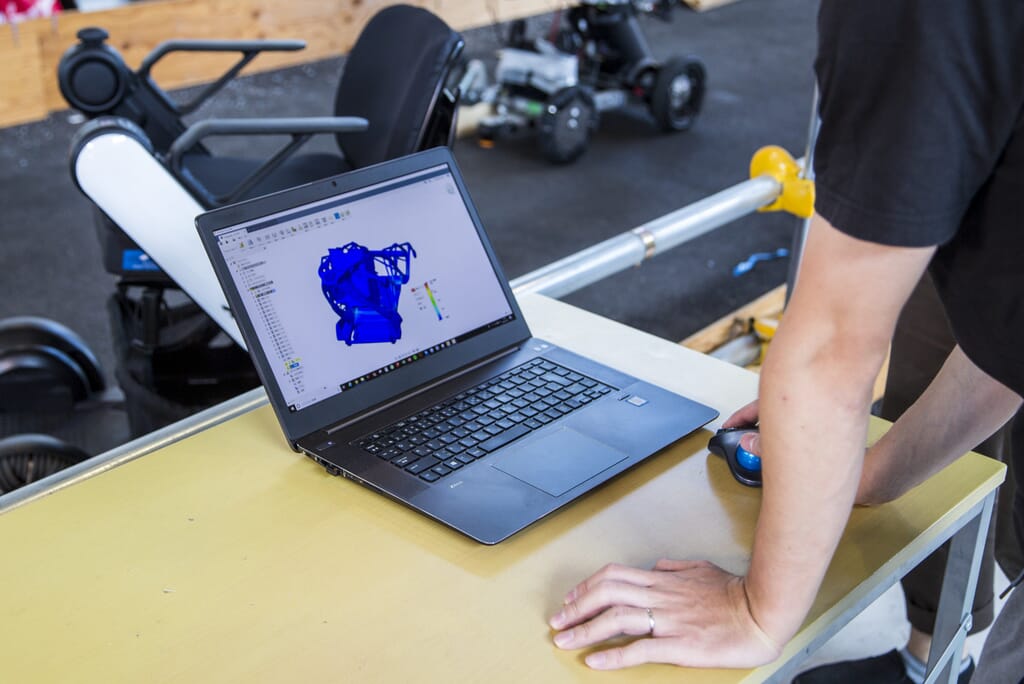

Autodesk Fusion 360 is cloud-based modeling, CAD, CAM, CAE, and PCB software for product design and manufacturing. The Fusion 360 platform offers the only truly integrated CAD and CAM software tool on the market. In addition to its base CAD and CAM features, Fusion 360 offers various Extensions to expand capabilities for specific roles. Fusion 360 Extensions allow designers to unlock additional features, such as advanced design and manufacturing technologies, access complex machining strategies, and generative design.

What are the Fusion Extensions?

The Autodesk Fusion 360 Machining Extension, offers several features not found in the base Fusion 360 package. This extension provides additional tool paths and functions, including:

- Steep and shallow strategy

- Enhanced tool orientation

- 5-axis and collision avoidance

- Rotary strategy

- Toolpath trimming — limiting

- Toolpath trimming — splitting

- Changing tools

- Deleting passes

- Probing geometry

- Inspecting surfaces

- Aligning parts

- Recognising holes

With these features and more, the Fusion 360 Machining Extension allows for enhanced machine programming and improved product development at an affordable price.

Enhanced Machine Programming

The Fusion 360 Machining Extension increases programming efficiency by implementing automation with ongoing product variability, repetitive tasks, and part quality. Steep and shallow automatically detects surface slope and applies the surface strategy. A single toolpath utilizes automatic 5-axis collision avoidance with advanced parameters to finish machining whole design parts.

The Machining Extension also provides customisable drilling templates to reduce repetitive tasks and increase efficiency. On-machine verification operations inspect both freeform and geometric features while the part remains in the machine. Inspection reports define what actions to take if the part is out of tolerance.

Automation minimizes human intervention, which, in turn, reduces production time.

An Affordable Option

Professional design, engineering, and manufacturing software tools are usually segmented by industry and sold separately. Fusion 360, on the other hand, combines functionalities, such as parametric modeling, stying, simulation, rendering, and CAM, all in one cloud-based platform. Now with Extensions, Fusion 360 expands specialised functionality without additional downloads or serial numbers.

To find out more about your options for Fusion 360 – or to get book on to some Fusion 360 training, get in touch with our team today.

Related Courses