Useability

Design Reservation

Previously if you and your team were working on a single Fusion 360 project, you had to be careful about who is making changes to which document. Changes saved to a document are versioned, however, it wasn’t easy to know who is working on what, nor was there a way to explicitly reserve a document. Now, the new Design Reservation feature makes this all possible by building on top of functionality that currently exists, as well as expanding on what is already possible.

If you and your team are working on an assembly with external components, you’ll notice avatars and reservation badges placed on the documents that you and your team members are currently working on. Badges will appear in the document tab, browser entities, and the data panel.

Design Reservations are a part of Autodesk’s Assembly Concurrency workflow. There is heaps more to cover on this top, so if its functionality that is relevant to you, be sure to check out one of their detailed blog posts on this subject.

Sketching & Modeling

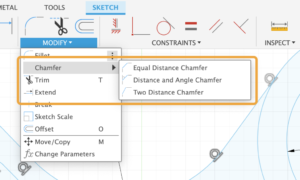

NEW Sketch Chamfer

Now under the Sketch > Modify drop-down menu, you’ll find not 1, but 3 Sketch Chamfer tools at your disposal: Equal distance, Distance and Angle, and Two Distance Chamfer.

Once you’ve selected the one you want to use, the Chamfer tool Feature options will appear in the Sketch Palette. This will make it easier for you to switch to a different Chamfer type, without needing to go to the toolbar. Liking this new feature? Learn more from Autodesk about chamfers in sketches.

Custom Parameters

Customer parameters are now automatically added to Favorites. Many Fusion 360 users have asked for this, and Autodesk is glad they can finally share it with you! Now when you created name dimension, that named dimension parameter will be automatically added to the Favourites section of the Parameters dialogue. With this improvement, you no longer have to go hunt down the right one and add it manually.

If you’re a Bommer user, this will be a pretty cool update for you, as you can use your named parameters to perform calculations inside your bill of materials. Want to learn more? Check out Bommers blog post.

Electronics

NEW Synchronizer Tool

Fusion 360 uses the Electronic Document to synchronize the schematic and PCB live. Meaning that changes done to the schematic will be instantly reflected on the board. There are times that this synchronization can be lost due to file corruption or working on one of the editors while the other one was closed. Traditionally, fixing PCB and Schematic annotation meant continuously running electrical rule checks and fixing each item manually. In this update, the synchronizer will enable you to restore consistency easily and automatically. It also paves the way for some exciting workflows in the near future.

Need to match an existing schematic with a PCB used in a different project? No problem! With the designs loaded, simply set up your synchronizer preferences, and in moments that PCB will be synchronized with the schematic. If you have ever run the diff tool in a text editor or IDE the interface will be familiar to you. It will provide you with a dialogue box listing the differences between the schematic and PCB. You will be able to selectively determine what differences from the schematic that will be transferred to the PCB.

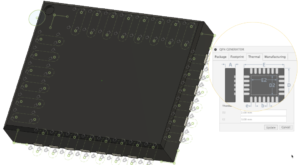

Package Generator User Interface

We think the package generator is by far one of the best tools in Fusion 360 because it allows you to create complex electronic components in a matter of minutes. A task that could take so much longer without it. In this update, all component options are now tabbed instead of a single scrolling dialogue box. This will make it much easier for you to access thermal options and manufacturing tolerances.

Generative Design

NEW Obstacle Offset Command

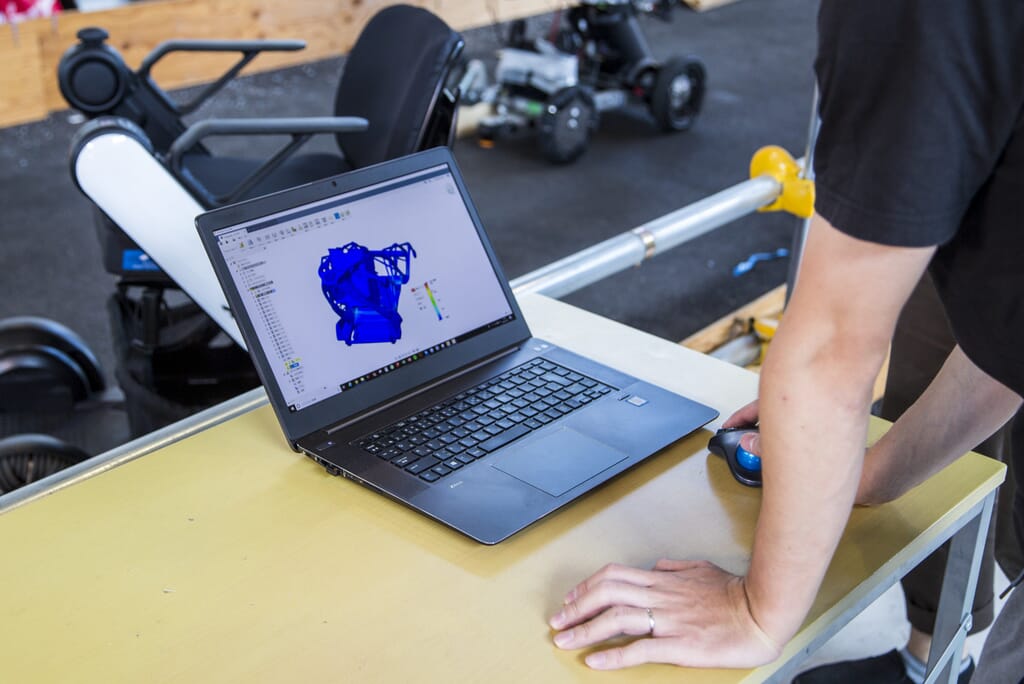

If you’ve been using generative design with obstacles in your design space, you have probably noticed a time or two that the generated geometry grew right up to your obstacles or even interfered with your obstacles around a tight corner, leaving an unexpected notch or cutout in your final shape because of the obstacles being cut from the generated geometry. The solution to this was to make your obstacles a little bit bigger and then remove the cut operation from the parametric recipe.

With this new update, Autodesk has added a new command – Obstacle Offset – that will allow you to virtually “inflate” your obstacles as part of the study setup without having to alter your original CAD geometry. The solver will now generate geometry based on this ‘inflated’ obstacle definition, giving extra clearance so that your generated geometry is sure not to touch or interfere with your actual obstacles.

Manufacture

NEW Post Processing to Fusion Team

In Autodesk’s drive to improve NC programs and unify the post-processing experience, they have added the ability to post-process directly to Fusion Team! The new “Post to Fusion Team” option allows you to not only post code as a regular NC program but automatically uploads that posted NC file to your Fusion team, creating a much tighter integration to the cloud.

With this, your NC file will have its own revision control and a link directly back to the reference document. It’s now easier than ever to stay up to date with the latest NC file, go back to an earlier version or even share a link with the shop floor to download the NC code.

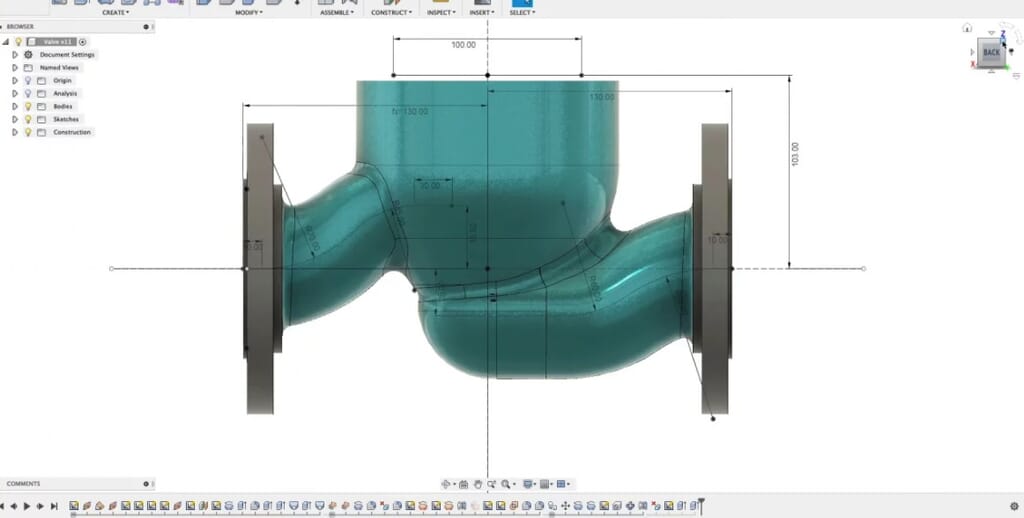

NEW Probe Geometry Inspection Report

Consolidation of Probe Geometry into inspection reports. Measure critical features and dimensions, confirm that they are within required tolerances, and record the results in Fusion 360. Inspired by the reporting capability from PowerInspect this functionality allows you to include all types of measurement results in a single consolidated inspection report. It imports results printouts created by probing cycles (such as Renishaw Inspection Plus) and provides the additional benefits of graphical reporting and the ability to format and export inspection results. Autodesk has extended the capability since the original preview In October 2020 and updated the colour conventions used to highlight whether results are in or out of tolerance.

Want to discover Fusion 360 for yourself? Get in touch with our team for your own demonstration.

Related Courses