One of the most common questions we get here at Cadspec is – “Is Fusion 360 better or Inventor?”. Although a very valid question, both play their part in the design process. Below we discover more.

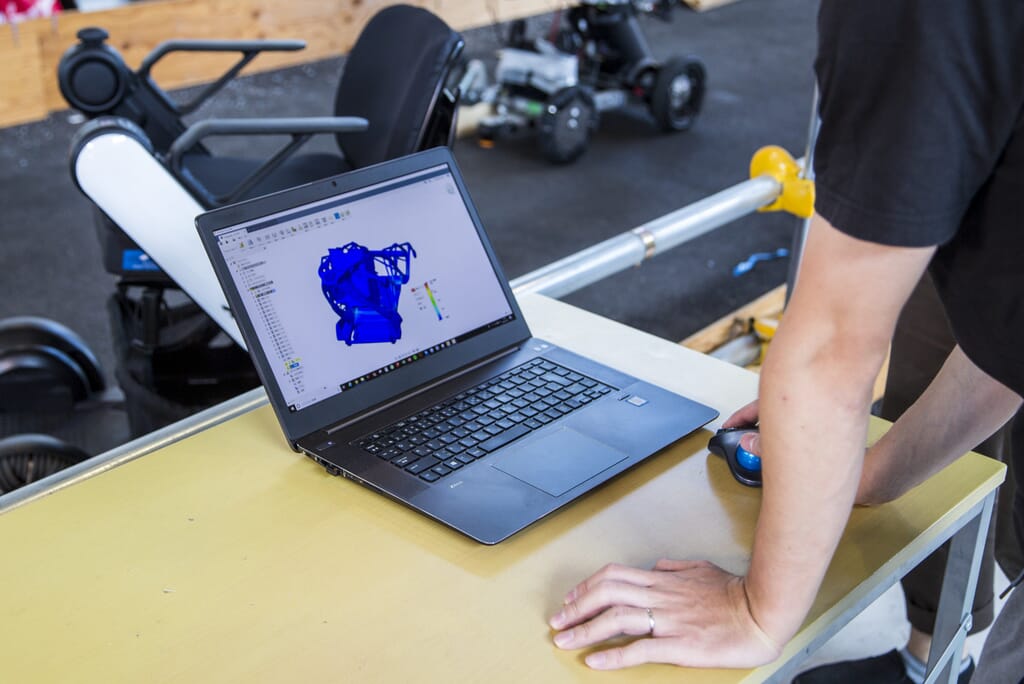

One of the key features of Autodesk Inventor is its parametric modeling capabilities. This allows users to create and modify parts and assemblies using constraints and parameters, which makes it easy to make changes to designs without having to start from scratch. Inventor also includes a variety of simulation and analysis tools, such as stress and motion analysis, which allows users to test the functionality and performance of their designs. Additionally, Inventor has a built-in rendering engine that allows users to create photorealistic images of their designs, which is useful for presentations and marketing materials.

When it comes to data management and collaboration, Autodesk Inventor has several tools that allow users to work with large and complex data sets. The software has a built-in data management system that allows users to organise and manage their designs, as well as collaborate with others in real-time. Inventor also includes a variety of tools for working with other CAD and CAM software, such as the ability to import and export data in a variety of formats.

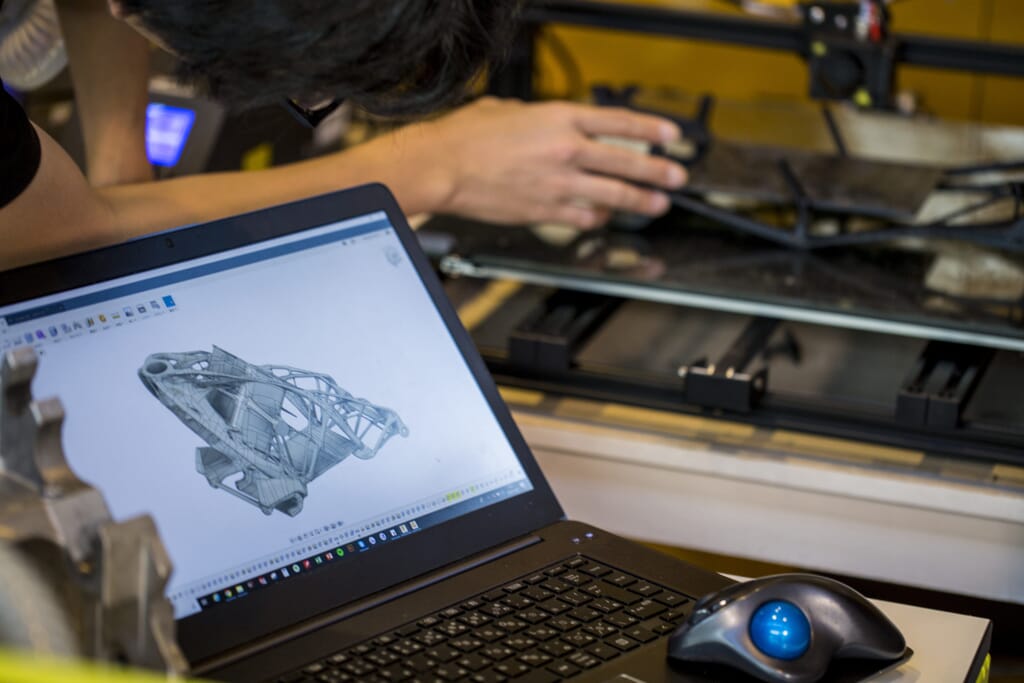

On the other hand, Autodesk Fusion 360 is a more versatile and comprehensive CAD program. It is geared towards product design and development, and offers a wide range of capabilities that go beyond mechanical design such as parametric and direct modeling, simulation, animation, rendering, and more. Fusion 360 is more suitable for designers and engineers who need a wide range of capabilities, like the ability to create complex shapes, or a need to simulate and test the dynamics of their designs. Additionally, Fusion 360 has a built-in CAM (computer-aided manufacturing) functionality which allows users to prepare models for CNC machines.

One of the key features of Autodesk Fusion 360 is its direct modeling capabilities. This allows users to create and modify designs without the need for constraints and parameters, making it easy to make changes to designs quickly and easily. Fusion 360 also includes a variety of simulation and analysis tools, such as stress and motion analysis, which allows users to test the functionality and performance of their designs. Additionally, Fusion 360 has a built-in rendering engine that allows users to create photorealistic images of their designs, which is useful for presentations and marketing materials.

Still not sure on which software is the best choice for you and your business? Our manufacturing team recently had an in-depth discussion on this very topic that hopefully answers any further questions you may have.

Related Courses