Fusion with PowerShape

PowerShape is CAD software for complex parts, electrode design and modelling for manufacture.

-

Why PowerShape? Overview

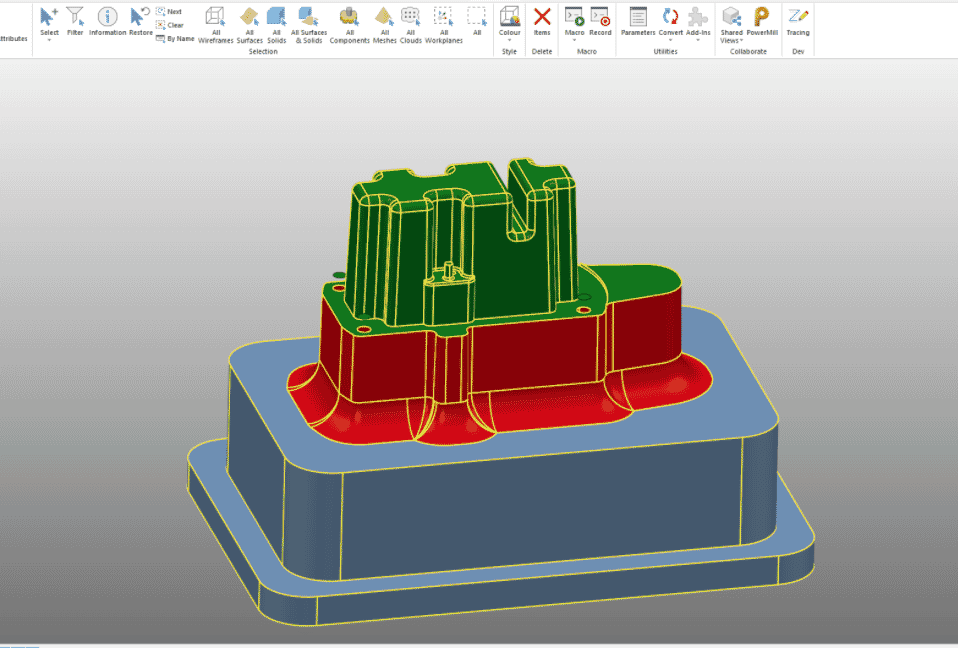

Fusion 360 with PowerShape manufacturing CAD software combines surface, solid, and mesh modeling to help prepare moulds, dies, and other complex parts for manufacture. Includes access to Fusion 360 and Fusion 360 Team. Autodesk created one package from this software to prevent data loss caused by file incompatibility. It also provides you with the various software that you’ll need during the product development process.

Boost CAM Programming

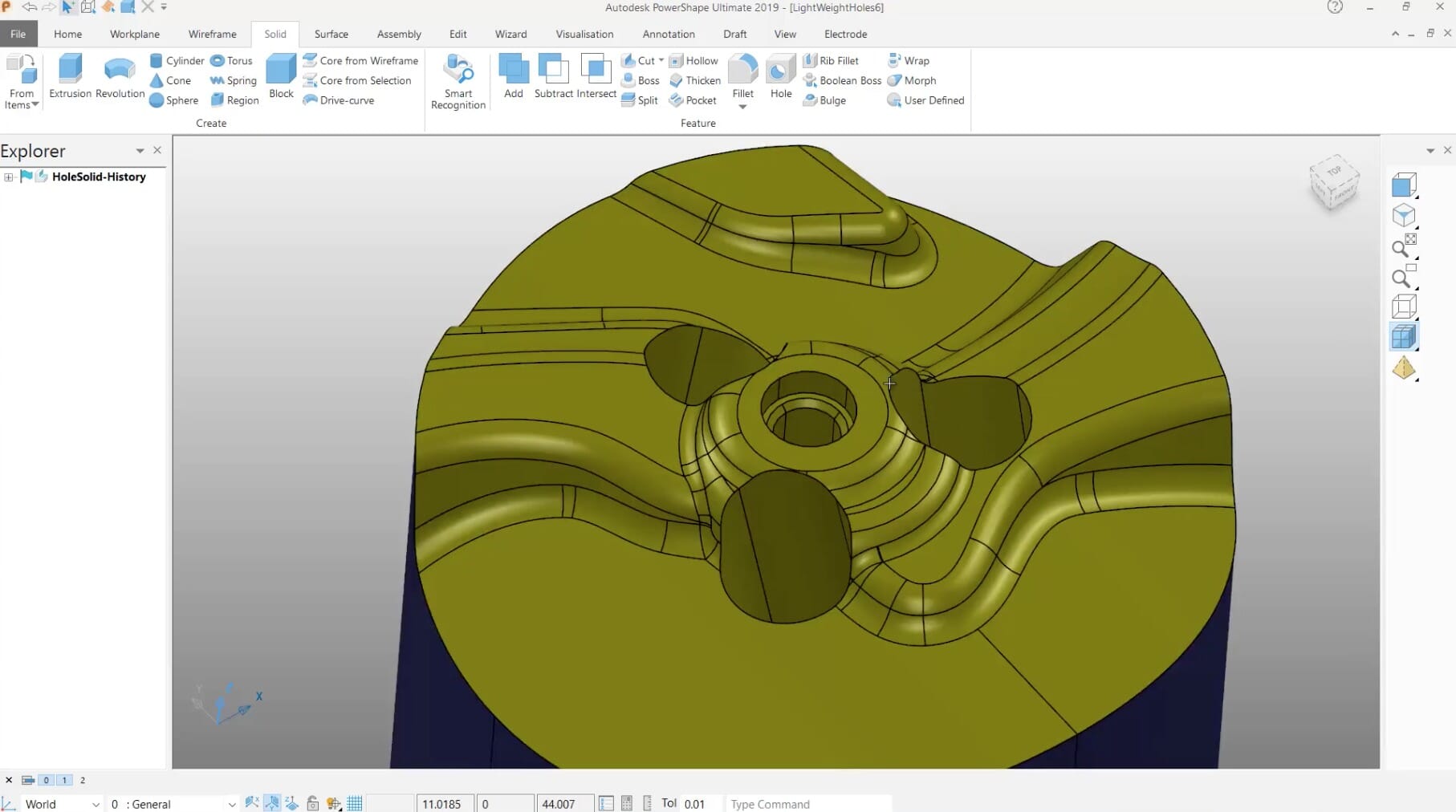

Create complex 3D geometry to better control CAM software such as PowerMill and FeatureCAM.

Modeling for Manufacture

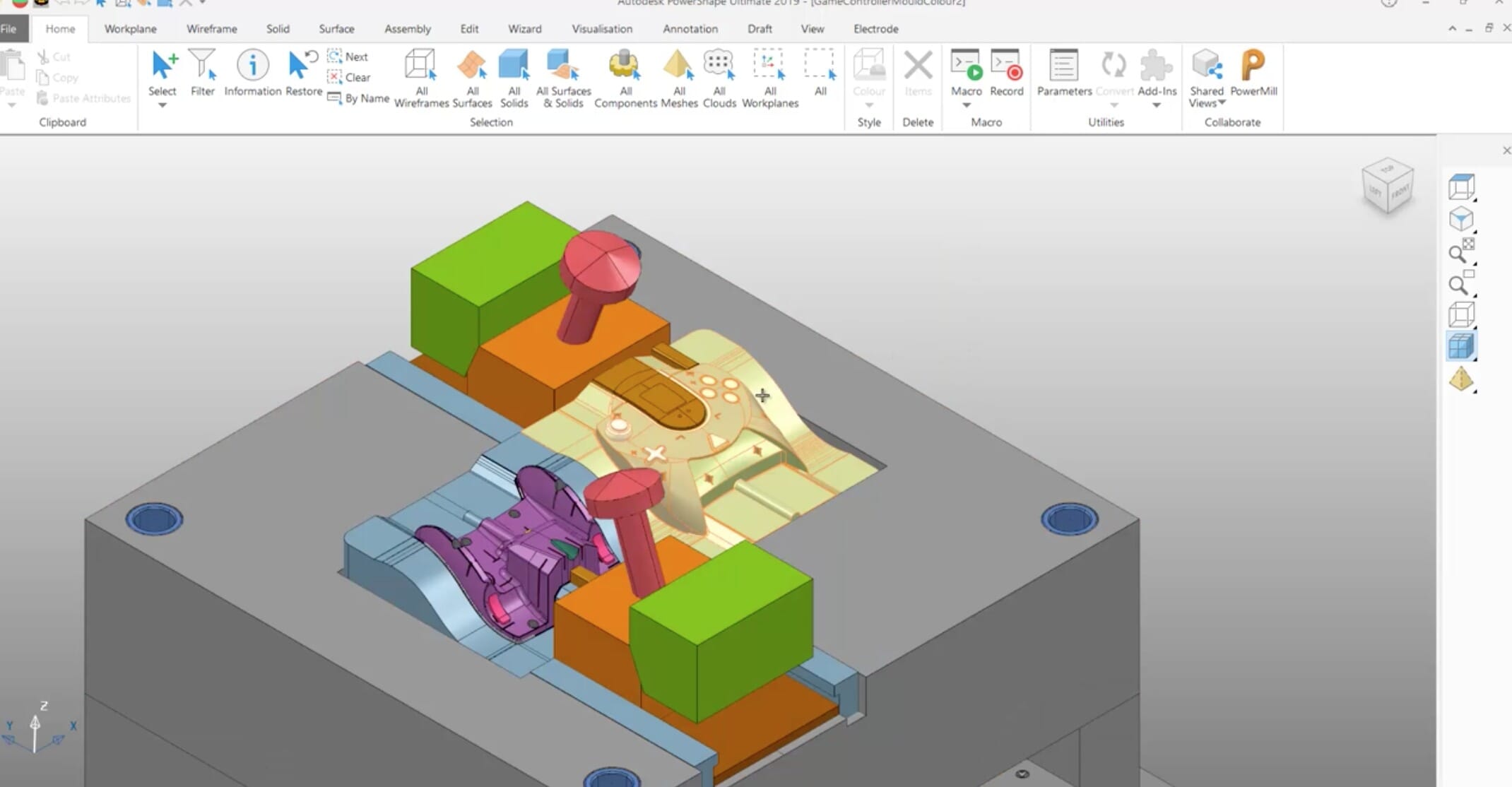

Access wizards in PowerShape to automate common modeling tasks. Quickly convert product designs into moulds, tools, and dies ready for CNC machining.

Read MoreElectrode Design

Creating an electrode design is now made much easier with PowerShape Ultimate. All kinds of tools such as the electrode wizard and the electrode integration in PowerMill can help you with this.

Cloud Based

Autodesk Fusion 360 is the world’s first cloud-based product innovation platform. This innovative software from Autodesk equips you with design software, engineering software, and CAM software in a single package. This software connects every step of your product development process.

-

Frequently Asked Questions

-

What are PowerShape's main features?

PowerShape has several modules that make engineering easier. Here are the 7 best features this software offers across the modules: Designing of Molds for Casting Processess, Electrode Wizard, Rib Capping, Reverse Engineering through 3D Scanning, Integration with other Autodesk Software, Autodesk Drive and boasts an intuitive user interface.

-

What exactly is PowerShape?

PowerShape is known as Autodesk’s ‘top of the class’ CAD solution, which goes above and beyond when it comes to versatility and functionality. It allows for the perfect designing of complex geometries and can facilitate the design and various parameters of moulds, tools, and other complex parts.

-

What are PowerShape's main features?

-

PowerShape Software Reviews

"Re-engineering old parts using 3D Scans"PowerShape is an incredibly powerful software that we use. It enables us to design the mould, then we move the mould geometry over to PowerMill & develop toolpaths to produce that mould.Tool Room Manager | Steele Rubber Products"Streamlining EDM Manufacture"In PowerShape we can extract the letters using direct modeling tools which is much quicker than what we had before. We are then able to create these script files that contain volume of the electro design, area of the electro design and tool change.EDM Leader | Cavalier Tool & Manufacturing

There are a range of options available – for a bespoke quote, please get in touch