Discover the key to an easy transition from SolidWorks to Fusion 360 with this helpful guide. Experience a seamless onboarding process and access the vital resources and knowledge essential for your success. While primarily tailored for SolidWorks veterans, it also proves beneficial to any new ambitious learners of Fusion 360.

Transitioning from SolidWorks to Fusion 360 opens up exciting possibilities for designers and engineers. As you transition, there are action items to keep in mind to ensure a seamless workflow shift.

Step 1: Get familiar with the Interface

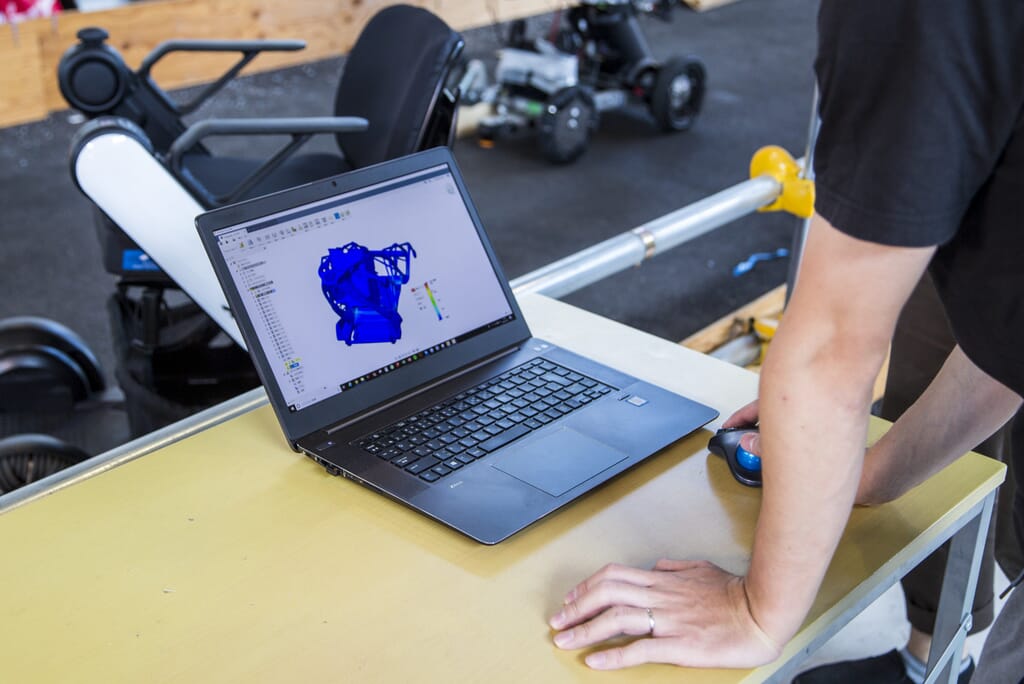

The interface serves as a pivotal element in the user experience of any design software, and Fusion 360 is no exception. As you embark on your Fusion 360 journey, the interface welcomes you with a sleek design that strikes a balance between functionality and simplicity. Familiarising yourself with the Fusion 360 interface is crucial to unleashing its full potential and harnessing its robust capabilities.

To navigate the interface proficiently, take the time to acquaint yourself with the diverse array of menus, tools, and panels at your disposal. At the top of the interface, a toolbar offers swift access to frequently used tools and commands. On the left-hand side, the Model Browser empowers you to efficiently organise and manage your design components, sketches, and construction features. Situated at the bottom, the Design Timeline emerges as a potent feature, recording the history of your design. This timeline enables you to revisit and modify past actions at any stage of your design process.

Step 2: Master Key Terminology

As you immerse yourself in the world of Fusion 360, pay attention to the terminology and structure specific to this software. While certain concepts and tools may bear resemblance to other CAD software, Fusion 360 boasts its own unique language and workflow. Gaining a solid grasp of fundamental concepts such as sketches, components, assemblies, parametric modeling, and design history features will empower you to effectively harness the capabilities of Fusion 360.

Take the opportunity to navigate through the workspaces, menus, and tools, and capitalise on the heaps of learning resources available. With a little dedicated practice, you will swiftly find yourself unleashing the full potential of Fusion 360, breathing life into your design concepts with ease.

Shifting your 3D modeling workflow from SolidWorks to Autodesk Fusion 360

If you’re contemplating the move from SolidWorks to Fusion 360, you might be curious about the process of transferring your 3D modeling techniques. Rest assured, the transition is more manageable than you might think.

Fusion 360 presents a compelling combination of transferable modeling techniques and an intuitive interface, simplifying its adoption and integration into your design workflow or business operations. With Fusion 360, you’ll find familiar elements such as sketch-based parametric modeling, mesh modeling, and T-splines, along with seamless integration of sheet metal design. This ensures a seamless transition from SolidWorks and minimises the adjustment period required.

Here are seven key Fusion 360 terms and features to familiarise yourself with:

- Fusion 360 workspaces – At first glance, you’ll notice the different workspaces available in Fusion 360. Each workspace (model, sculpt, patch, etc.) is tailored to a specific design task. This allows you to focus on the tools and functionalities relevant to your project.

- Assemblies in Fusion 360 – Fusion 360 enables you to create complex assemblies by streamlining a number of modeling systems for ease of use. Multiple components, bodies, externally referenced parts, and even third-party CAD are all ways a single large assembly can be assembled in Fusion 360.

- Sketch based parametric modeling – Parametric modeling allows you to create intelligent, feature-based designs that capture design intent and enable easy modifications. Understanding how to leverage parametric design in Fusion 360 is a must. It will enable you to maintain design intent and easily make design changes.

- Mesh Modeling – In addition to sketch-based modeling, Fusion 360 offers powerful mesh modeling capabilities. The intuitive mesh modeling tools allow you to create and refine intricate, organic shapes with precision. This opens up new possibilities for designers working on complex designs or artistic projects. The mesh modeling workflow in Fusion 360 seamlessly integrates into its interface, ensuring a straightforward transition from SolidWorks to explore the world of mesh modeling.

- T-Splines – T-Splines in Fusion 360 (also called form modeling) add another dimension to your design capabilities. They allow you to create smooth, freeform organic surfaces while maintaining the parametric and feature-based benefits of sketch and direct modeling techniques in Fusion 360.

- Sheet Metal – The seamless integration of sheet metal design in Fusion 360 further enhances its versatility. You can leverage parametric modeling tools to create accurate sheet metal components, unfold them into flat patterns, and simulate their fabrication and assembly.

- Fusion Team – One of the critical features of Fusion 360 is Fusion Team, a collaborative workspace that enables teams to work together efficiently. Fusion Team provides a centralised hub for storing, organising, and managing design files, allowing team members to access the latest versions and collaborate in real-time.

Migrating legacy designs from SolidWorks to Autodesk Fusion 360

Fusion 360 offers seamless integration with SolidWorks files, allowing you to import your existing CAD data and convert it to the history-based modeling format Fusion 360 offers, making the transition smooth and effortless.

How to import files in to Fusion 360

Fusion 360 offers a user-friendly import feature tailored specifically for SolidWorks files. Simply select the desired SolidWorks file for import, and Fusion 360 will intelligently recognise the file format and import the CAD information into its environment. This eliminates the need for manual reconstruction or redesign, saving you time and effort.

Once imported, the history-based modeling feature in Fusion 360 allows you to leverage the CAD information from SolidWorks effortlessly. This capability enables you to modify, iterate, and adapt your existing designs within Fusion 360 with ease. By preserving the model history, Fusion 360 empowers you to make design changes efficiently while preserving the integrity of your original SolidWorks data.

File Support

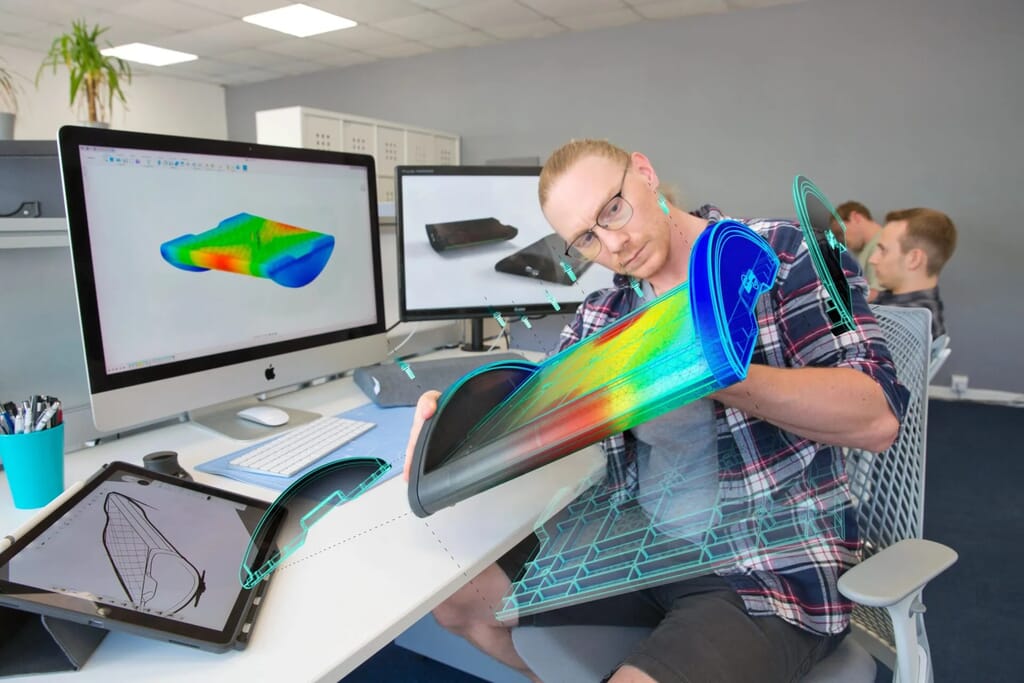

One of Fusion 360’s standout features is its remarkable ability to open and handle various CAD file types across its diverse workspaces. Whether your focus lies in manufacturing, modeling, rendering, ECAD (electronic CAD), or simulation, Fusion 360 offers seamless compatibility with a wide range of industry-standard file formats. This extensive compatibility ensures that you can effortlessly incorporate legacy SolidWorks designs at any stage of your design and manufacturing workflow within Fusion 360.

In the manufacturing workspace, you can leverage imported SolidWorks files to generate toolpaths, simulate machining operations, and generate CNC programs. The modeling workspace empowers you to refine and optimise your designs, utilising the converted CAD information to drive your parametric modeling process. Furthermore, the rendering workspace allows you to create realistic visualisations and presentations utilising your existing SolidWorks data.

For electronic designs, Fusion 360’s ECAD capabilities support the import and manipulation of legacy PCB (printed circuit board) files, facilitating a seamless transition of your electronic designs from SolidWorks to Fusion 360. Lastly, the simulation workspace within Fusion 360 empowers you to conduct thorough analysis and testing using the converted SolidWorks data, facilitating the evaluation and validation of your designs.

Embrace Fusion 360 & everything it has to offer

The unique capabilities of Fusion 360 will help you discover new efficiencies and possibilities in your design process, ultimately enabling you to bring your innovative ideas to life with confidence and precision. With Fusion 360’s easy deployment, there is little to no downtime as you transition from SolidWorks, allowing you to adapt and continue working on your projects without disruption quickly.

If you are still unsure, we recommend getting in touch with Cadspec to discuss your training or support needs as our team are experts in the field of migration.

Related Courses