Autodesk Fusion 360 - is it worth the hype?

Cloud based you ask? Yes, indeed, behold- your design data, be that technical drawings, parts, assemblies, simulation studies etc, is kept safe and secure on the cloud, in a single location, with unlimited storage and access. If unlimited storage wasn’t enough you also get unlimited installs, and unlimited team member invites to your Fusion 360 projects. That gives the design team incredible flexibility to collaborate and create anywhere, with anyone in the world. Critical advantages in order to design products more efficiently.

Fusion 360 vs Inventor

Lots of people have asked this question since Fusions inception, and there are some great comparisons between the two- here is our take from experience.

While both of these programmes have incredible features and in terms of part modelling capabilities are fairly similar, Fusion does excel in quite a few areas. It is important to note however, that Fusion 360 is still in its infancy in CAD terms. Inventor is well into its early thirties release version whilst Fusion- only five. Being more established, Inventor has more power and stability which would be expected, and can manage larger assemblies more effectively. Greater functionality is also achieved in terms of advanced FEA simulation and time saving design accelerators.

Power of the Cloud

Fusion 360, is completely cloud based therefore, access and collaborative aspects of the software are smoother through my experience. Cloud based with unlimited storage alleviates some IT worries of design managers, which is always a plus. Users of Fusion get greater transparency throughout the design process. Everyone on the project can view, mark up and comment on 3D models and drawings, even on a mobile device. Fusion 360 enables everyone on your team to be on the same page, this means no time is wasted making sure everyone is on the right software version or what viewer they support or file formats they accept. Everything is self-contained! However, should you need to work with some non-native CAD formats, then fear not, as Fusion will happily take most other CAD formats, as will Inventor. It can be argued that Inventor, is definitely best in class at this particular feature.

The power of the cloud with Fusion 360 can be utilised further when it comes to rendering. All designers know the bane of leaving a machine on overnight to render that final product image, especially after meticulously setting up various lighting and environments. Doing this is fraught with risk, a simple power outage or machine overheat would lose the render, and let’s not forget leaving a machine on to render for hours is valuable time and energy wasted. Fusion 360 has it covered, designers can actively render in the cloud. When the render is complete the image will send itself to your machine. This means you can continue working whilst rendering.

It’s a complete 3D digital prototyping, validation and manufacturing programme

The most striking difference that sets Fusion 360 apart is that CAD, CAM & CAE are self-contained in one programme. This speeds up the design process as time is not wasted importing and exporting design data from one programme to another. Changes can be made quickly and efficiently, with updates to toolpaths being reflected in parts, assemblies and even technical drawings. Fusion provides the platform to allow designers to progress from the design stage to manufacturing in a much more organic and fluid way. Straight from the part or assembly model, designers can use the CAM capabilities of HSM within Fusion, to generate, optimise, simulate toolpaths, validate them, and then export straight to G-code.

Fusion also packs features that enable easy exportation to a 3D printer for rapid prototyping. Don’t let these manufacturing processes limit your design capabilities though, as Fusion 360 is more than equipped to design for a multitude of standard manufacturing techniques, as is Inventor.

Freeform Modelling

Fusion 360 not only enables designers to model in the conventional way, but also to completely sculpt 3D entities like virtual clay on screen. This in itself is impressive, and forms can be created with either push and pull commands, but using the bridge command allows transition from one form to another. Sculpt commands within Fusion give designers unparalleled flexibility to create organic and free flowing geometries that conventionally with surface modelling, would take much more skill and time to create. That being said Fusion 360 still packs all the surface commands Inventor does. Once freeform sculpted parts have been created designers can switch back over to parametric features like holes, bosses, or ribs, by simply switching the workspace in the ribbon. Easy.

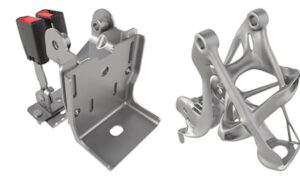

Generative Design Technology

All the rage and for good reasons, generative design add in for Fusion 360, allows designers to ‘mimic nature’s evolutionary approach to design’. Simply model as normal, input design goals into generative design software, along with parameters such as materials, manufacturing methods, and cost constraints. The software then using the cloud explores all the possible permutations of a solution, quickly generating design alternatives. It tests and learns from each iteration what works and what doesn’t, through in-built simulation. This results in incredibly efficient and organic parts that have material applied only where it is required. This process of model creation is highly suited to additive manufacturing where these complex forms can be generated.

So what do I buy? Inventor or Fusion?

This is actually a hard question to answer but also for the right reasons. Both programmes are exceptional in terms of 3D modelling and simulation. The real answer depends on your business requirements. Cadspec, are Autodesk Gold Partners and have been selling, training and consulting Autodesk software in the UK for over 20 years. We are ideally placed to review your CAD design requirements, whether architectural or mechanical, and find the right solution for you, that will both maximise productivity, improve accuracy, and provide the return on investment you require.

How easy is Fusion 360 to learn?

As easy as any other 3D CAD programme, as most designers/engineers have experience with some form of CAD, learning a new format is usually not too alien. Cadspec provide professional Autodesk accredited 3D CAD training for all Autodesk softwares that your business may require, including Fusion 360.

Top 5 Benefits of using 3D CAD Software

Technical drawings and plans are an essential part of many industries including engineering, civil electrical, architectural, building and manufacturing. The blueprints of these designs are an integral part of the construction process and contain important details such as scale, dimension and material information. It’s essential that these details are correct and can easily be accessed and altered; aspects which now demand the capabilities of digital technology.

Avoid Costly Mistakes

3D modelling solutions offer a much greater insight when creating designs. It gives you the ability to test stress factors and tolerances of a design before it’s built, saving both time and money as well as ensuring large problems are not found once the construction process has begun.

Work More Efficiently and Increase Designer Productivity

In 2D CAD, a lot more evaluation is required to ensure your plan, section and evaluation agree. However, with 3D CAD, architects and engineers can quickly and easily extract the 2D information from a completed model, creating more time to focus on the actual design process. Also, with 3D CAD each individual component of a structure can also be isolated, analysed, tested, approved or changed without accidentally altering other design components.

3D CAD software helps the designer in visualising the final products and its constituent parts. The product can be given animation to see how the actual product will work, meaning the designer can immediately make modifications as required. By viewing the 3D model in action, design flaws can be picked up faster and in turn allows for a faster design process, lowering the design cost and shortening the project completion time.

A Streamlined Design Cycle

3D design enables a faster product design process which is roughly 45% faster on average than 2D design!

Revisions in 3D CAD software are much easier and more economic than manual and 2D drafting as it doesn’t require a constant use of paper and ink. Also, each component can be separately edited without changing the overall design and if needed changes can be reverted.

It Can Help You Win Quotes and Keep Clients Happy

3D CAD software enables you to give clients and prospects a virtual tour of their building/ design. The 3D model shows clients a polished and interactive visual representation of their final product. 3D designs also offer clients more customisation options since individual design elements can be changed with ease. And since the software is designed for customisation, it won’t cost you any extra.

Visualise Your End Product

Utilising 3D software with interactive 3D drawings enables users to create more ‘what if’ scenarios, reducing the margin for error. There is also a point-click animation feature which makes it easy for anyone to interpret and understand the design data.

So there you have the top 5 reasons why you should embrace 3D CAD software. Here at Cadspec we have a range of Autodesk CAD products which are specifically designed for different industry uses. Call us now or visit our website to find out which Autodesk 3D CAD software is most suitable for your business needs